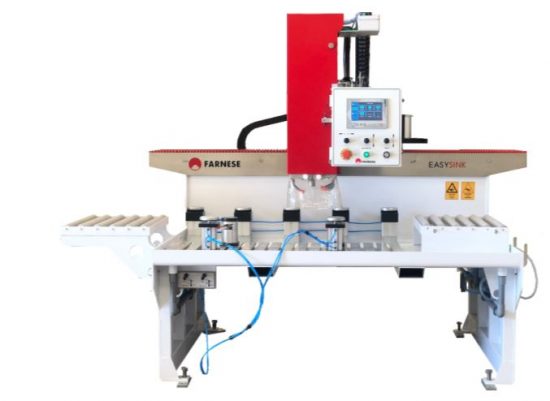

Description

TECHNICAL DATA

TECHNICAL DATA

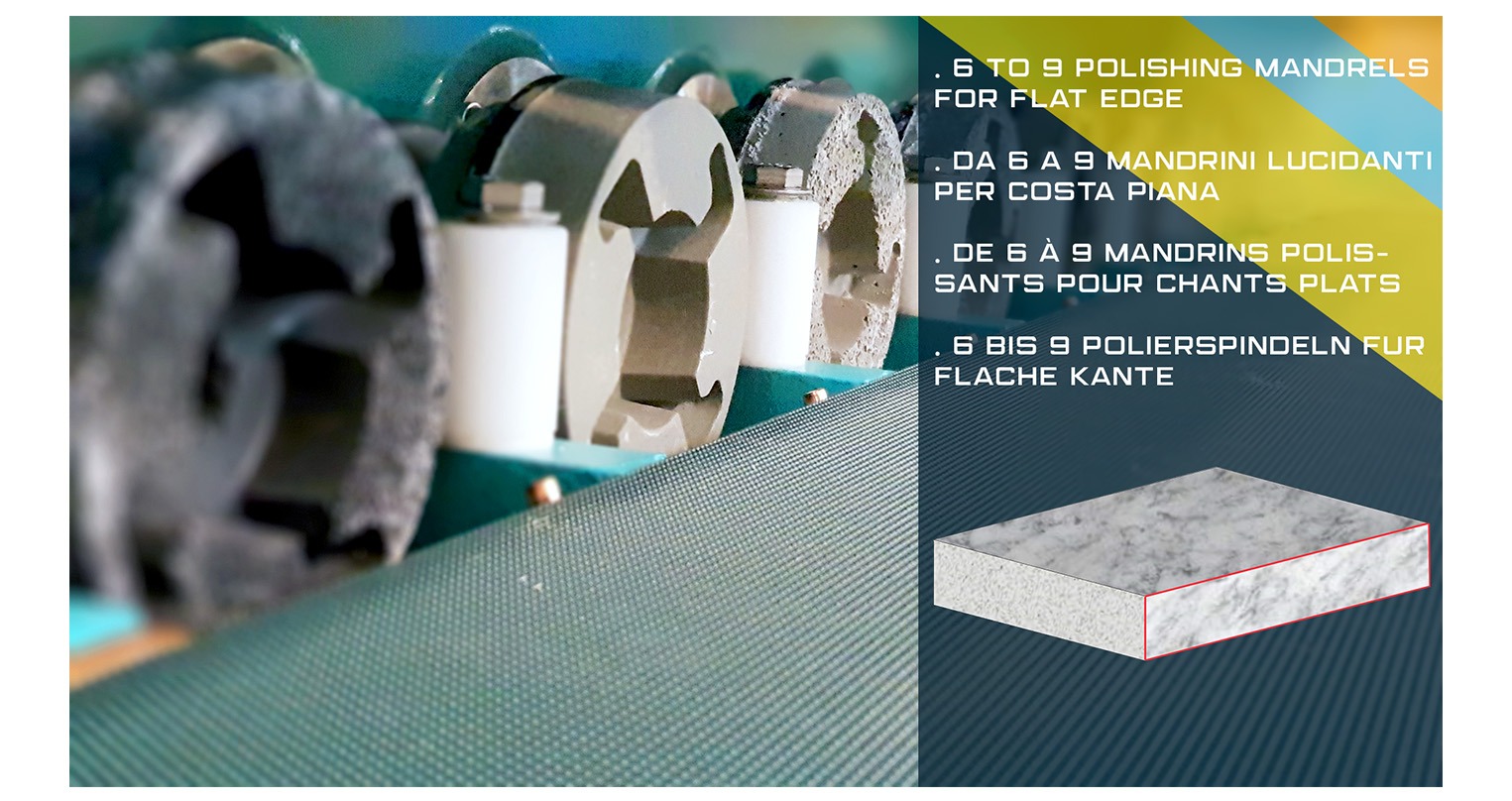

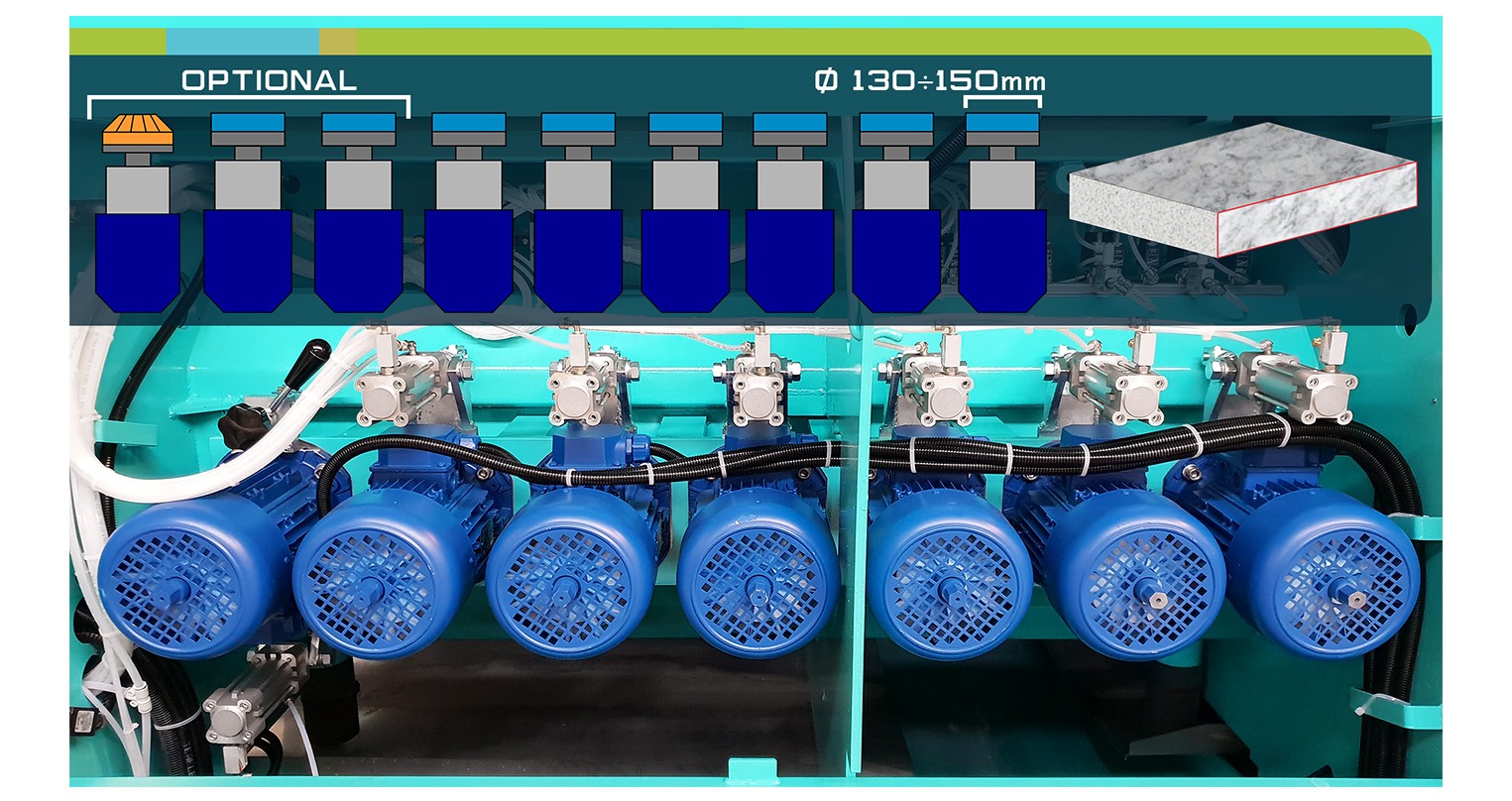

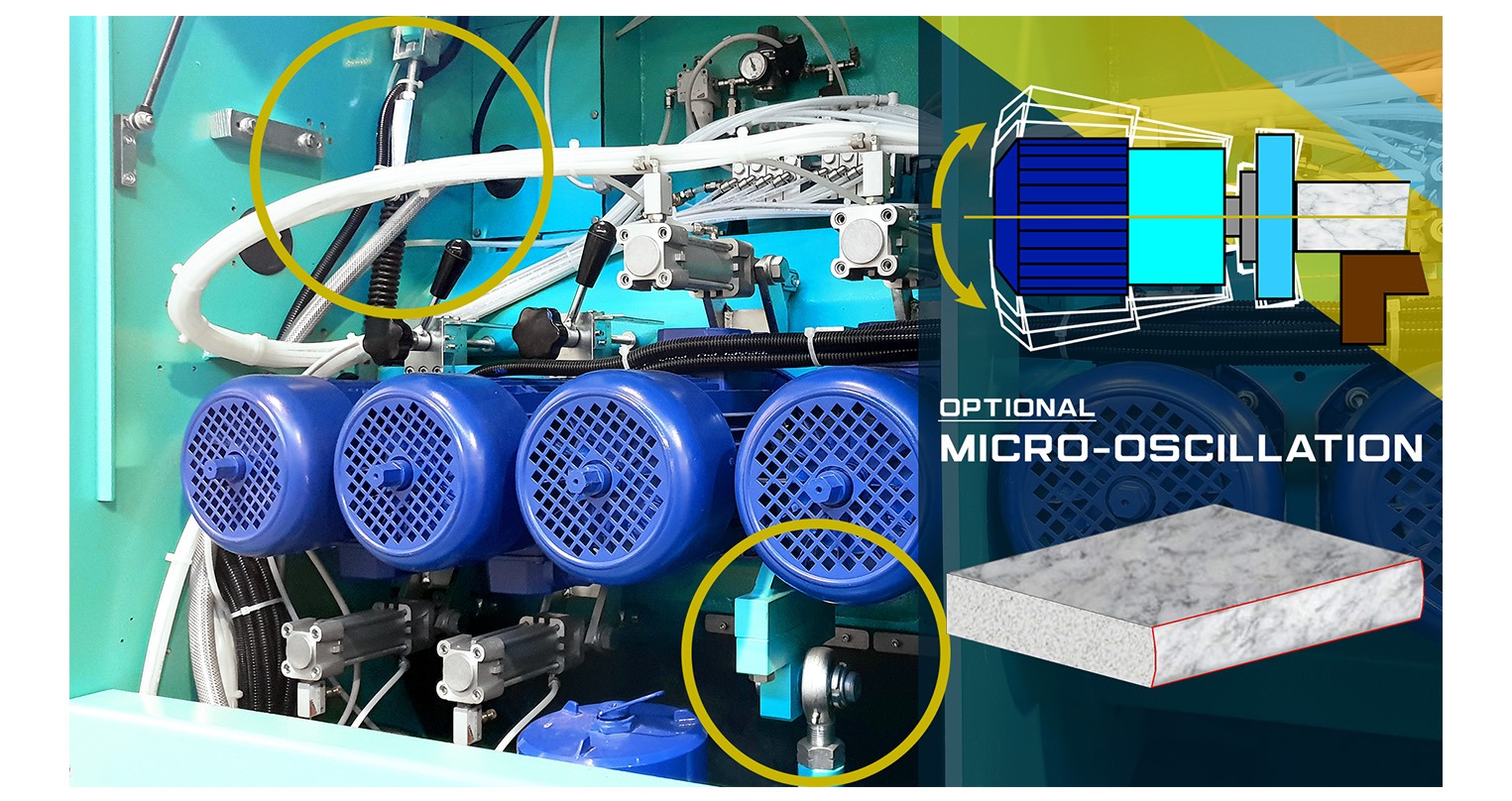

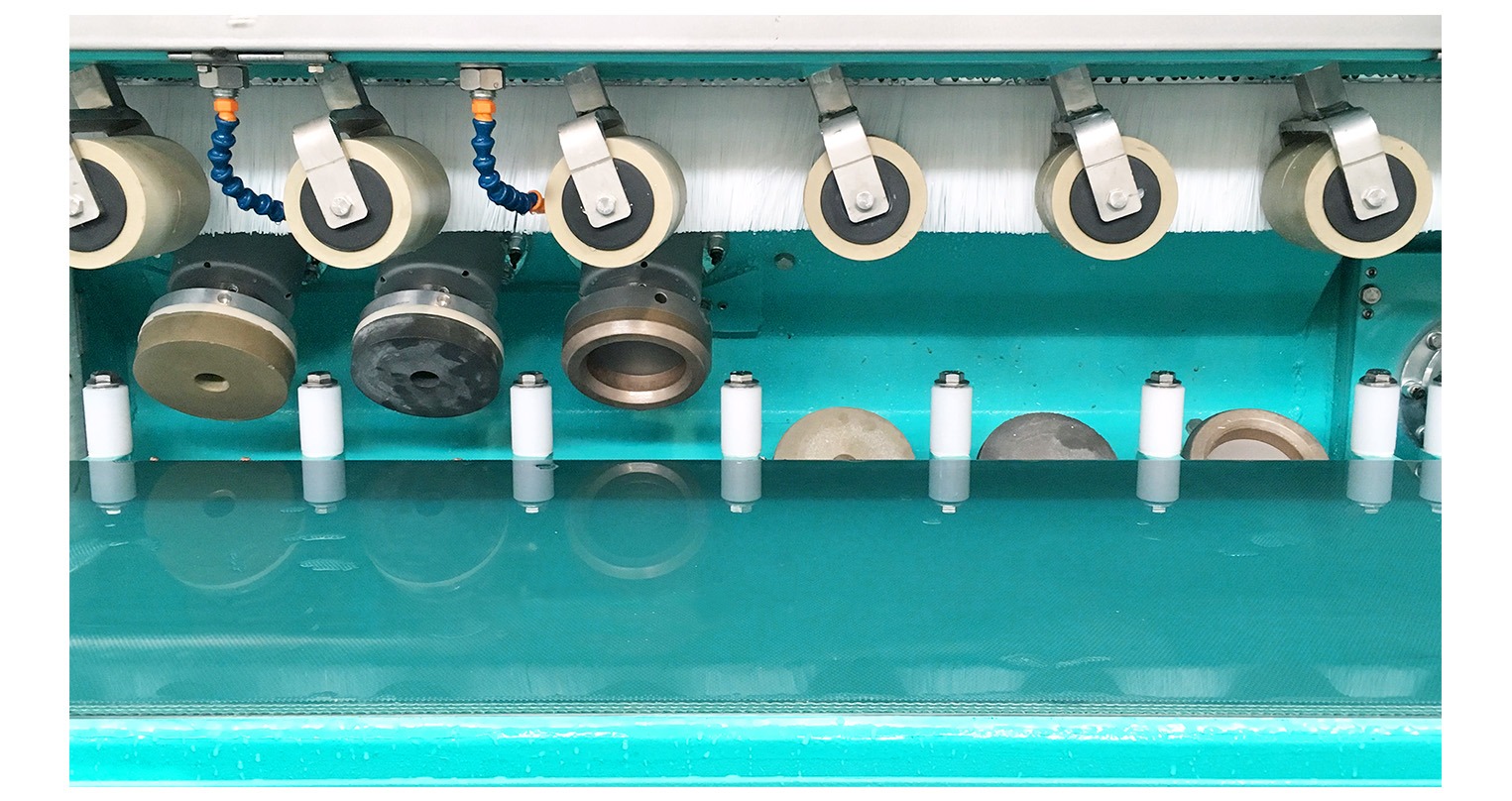

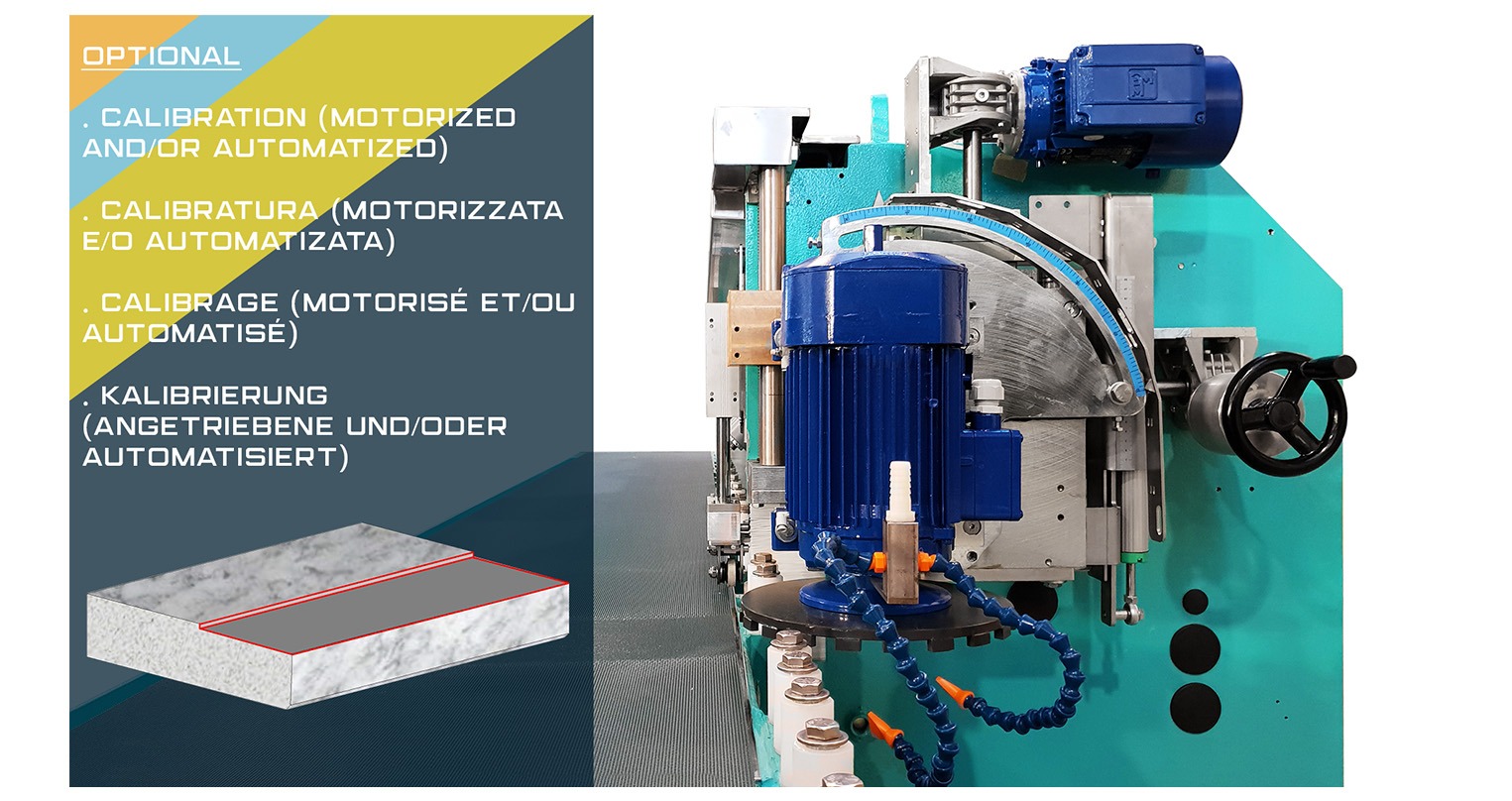

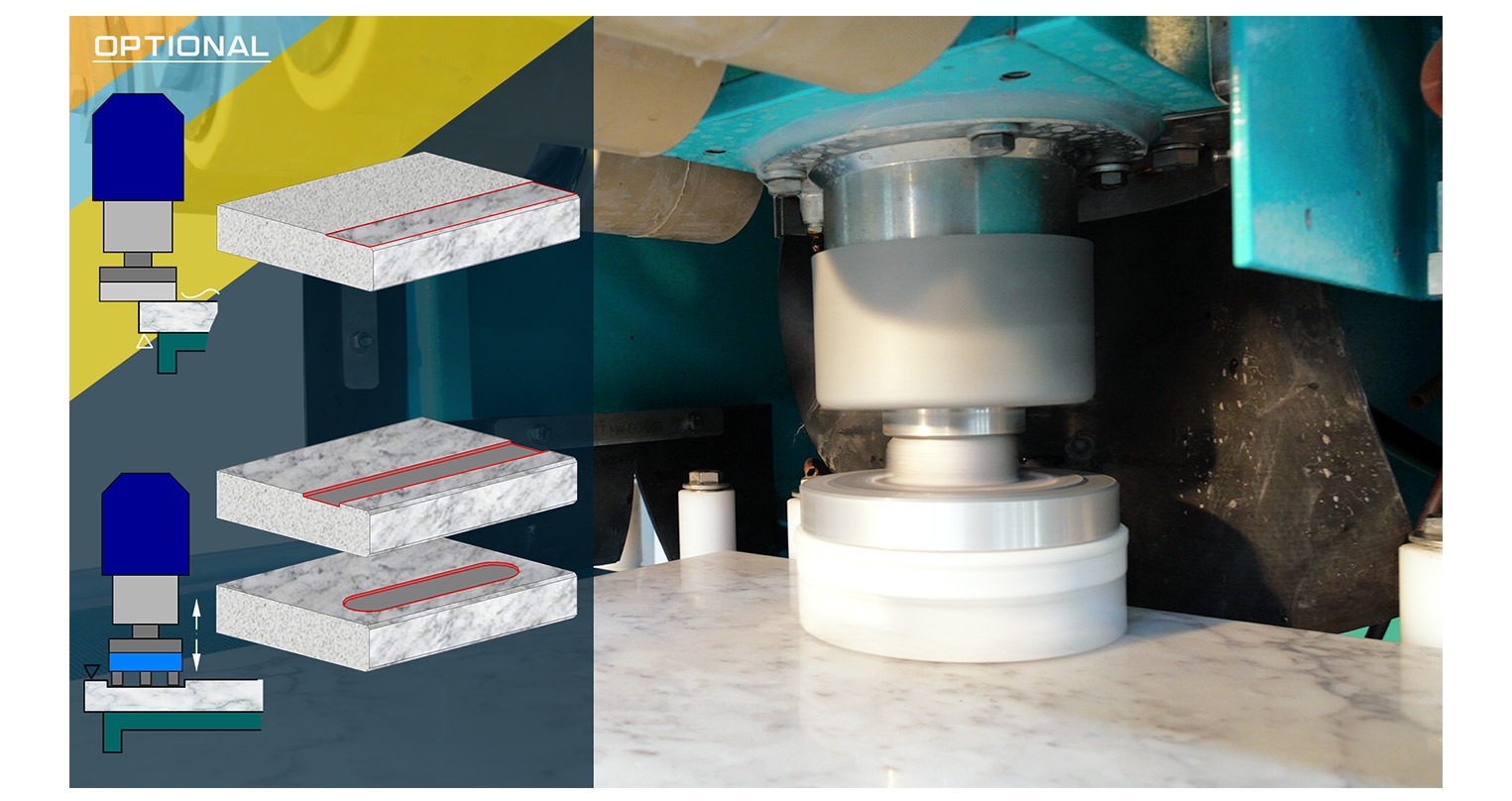

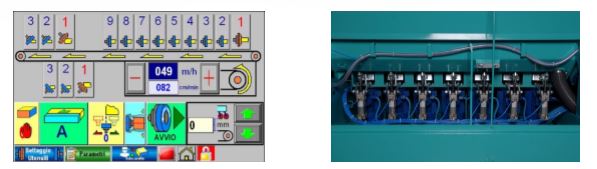

Number of Polishing Motors: 7

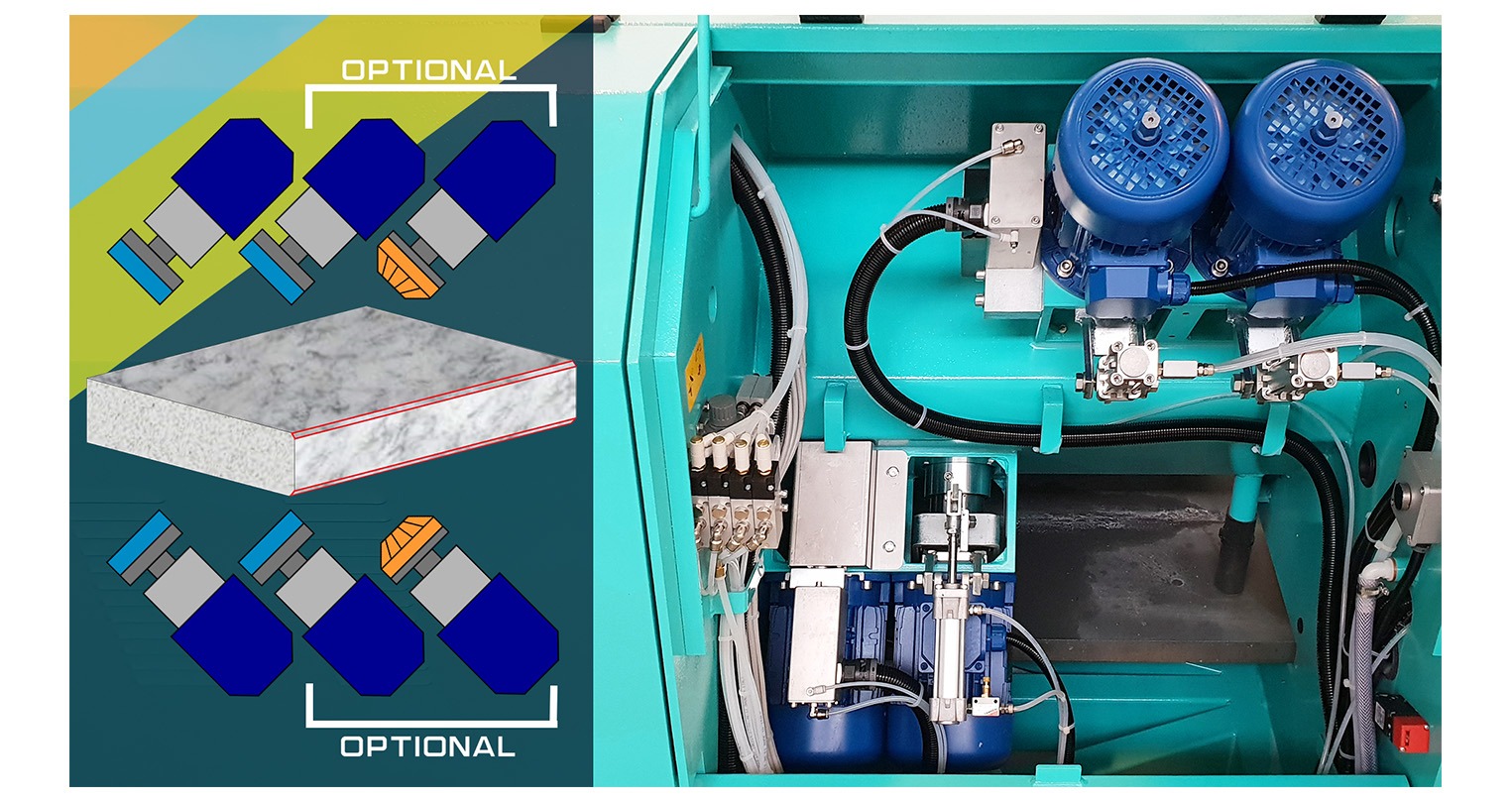

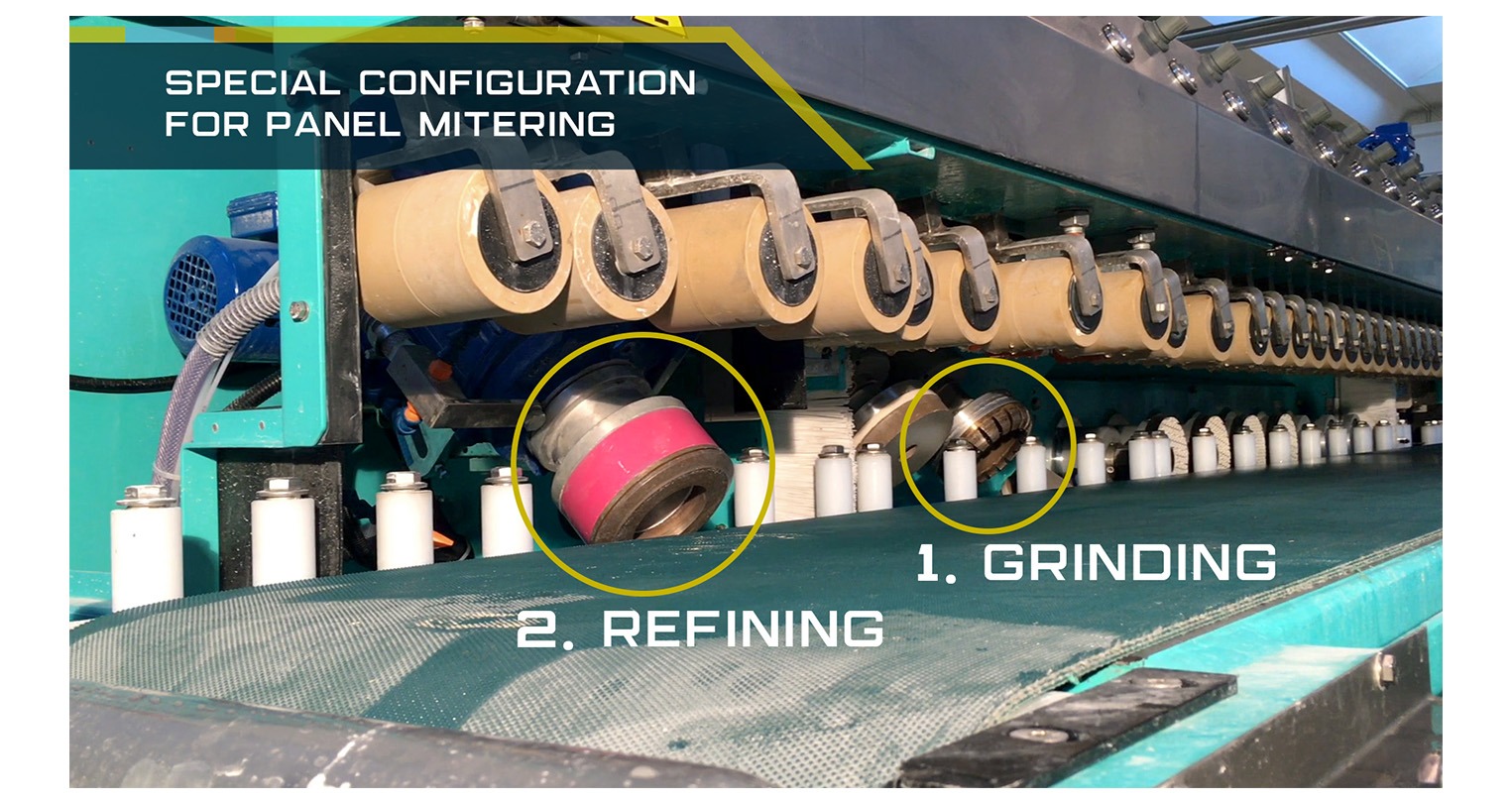

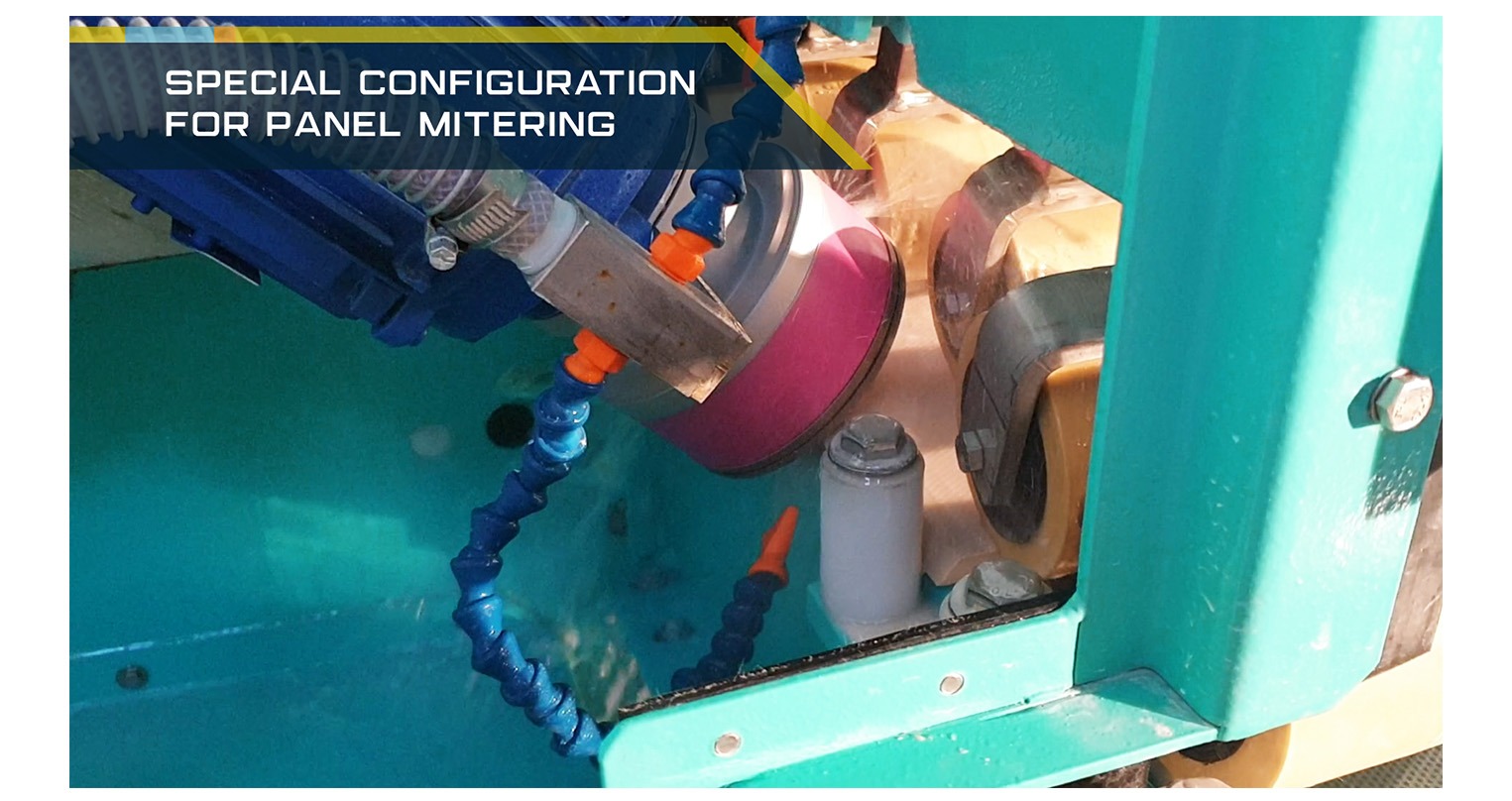

Number of Beveling Motors: 2

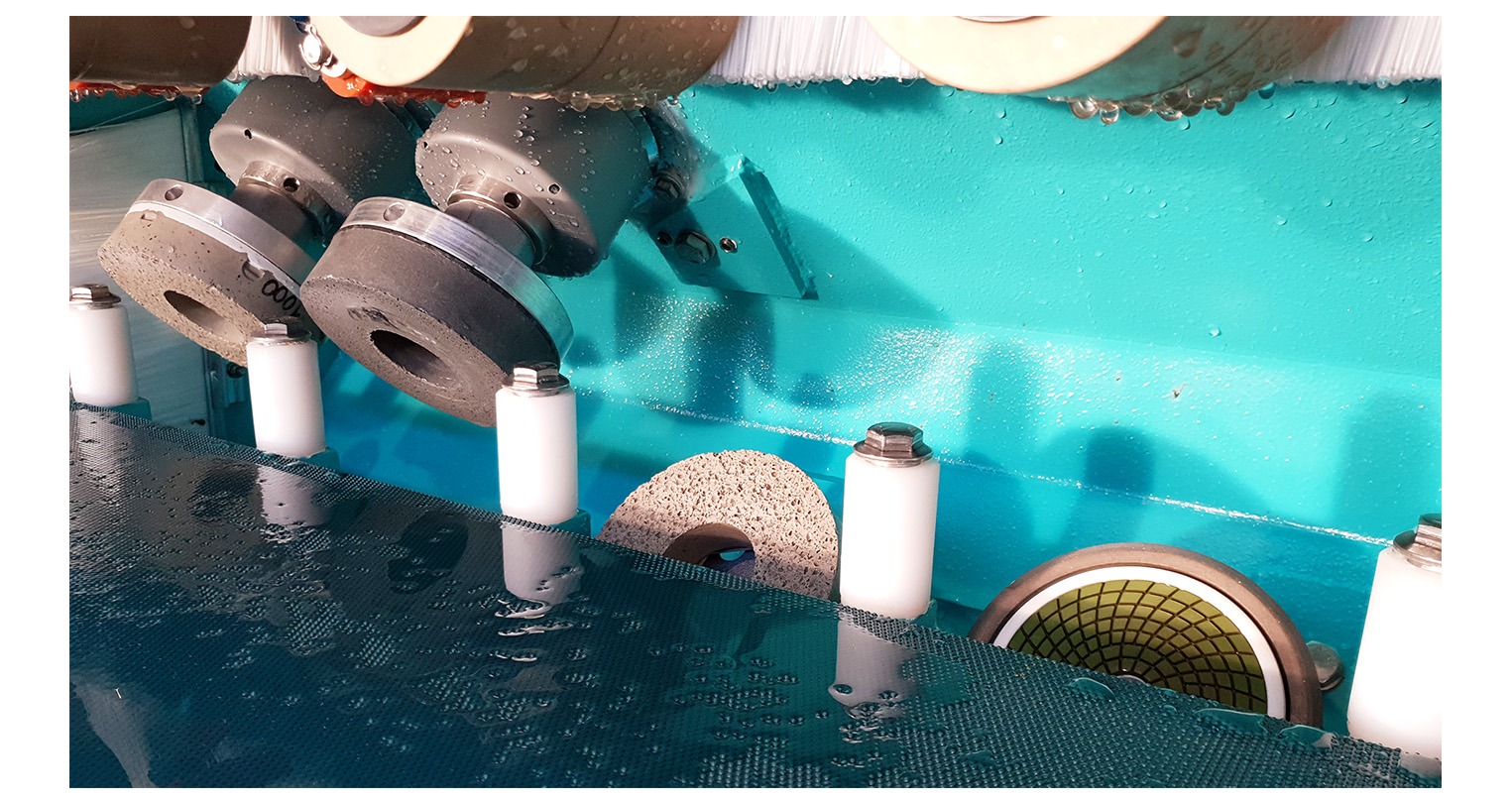

Total Water Consumption: 45 – 55 litres/minute (12 to 15 gallons/minute)

Total Dimension of Machine: 3m X 1.22m X 1.22 m (10ft x 4ft x 4ft)

Total Weight of Machine: 1.36 Tonnes (3,000lbs)

Working Speed: 45m (150 feet) per Hour

Maximum Abrasive Size: 6″ or 150mm

Minimum material size: 3 inches x 16 inches 75 mm X 400 mm

Maximum material size: NO MAXIMUM

Extension Tables: Standard 3ft in length

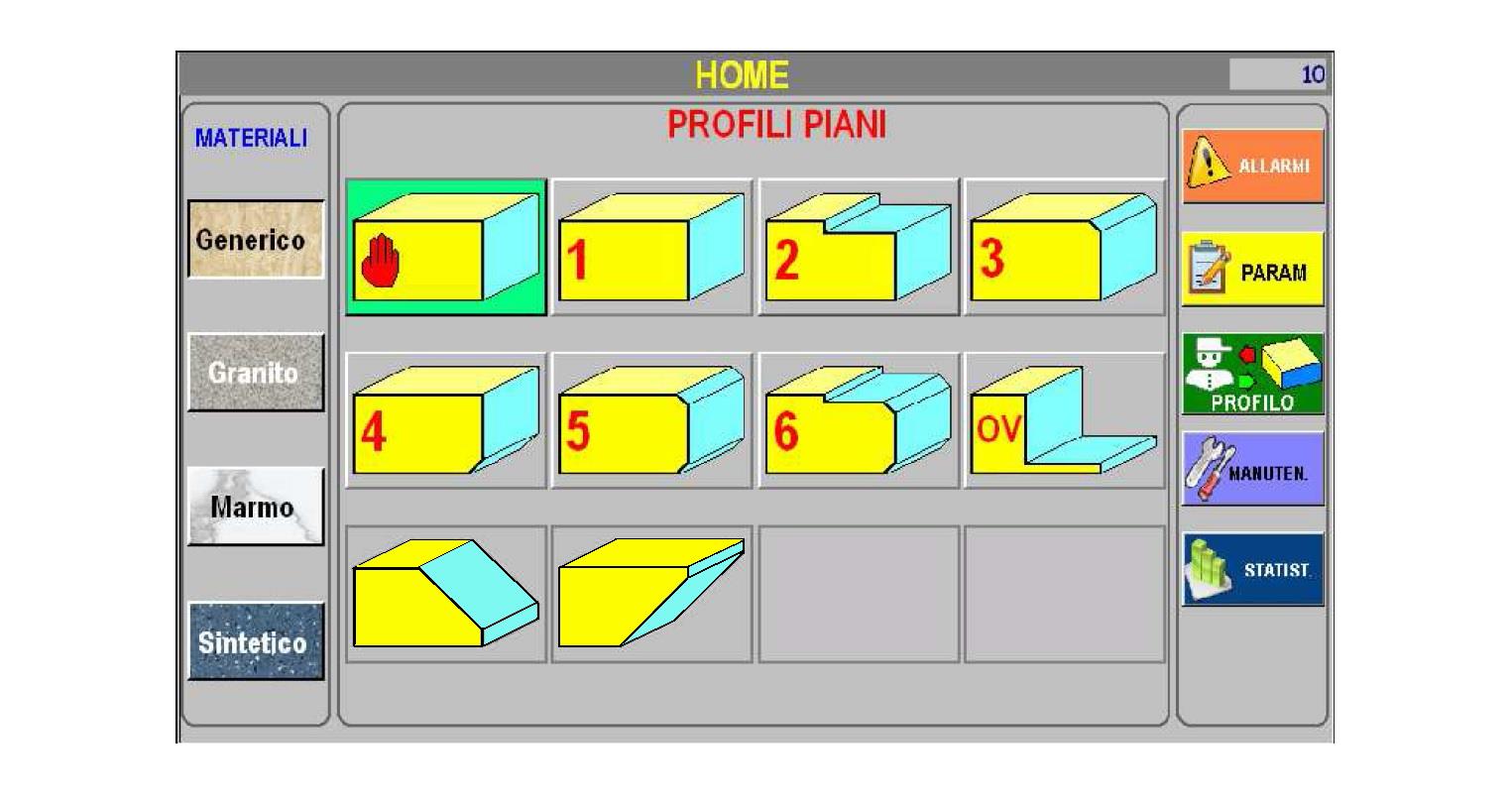

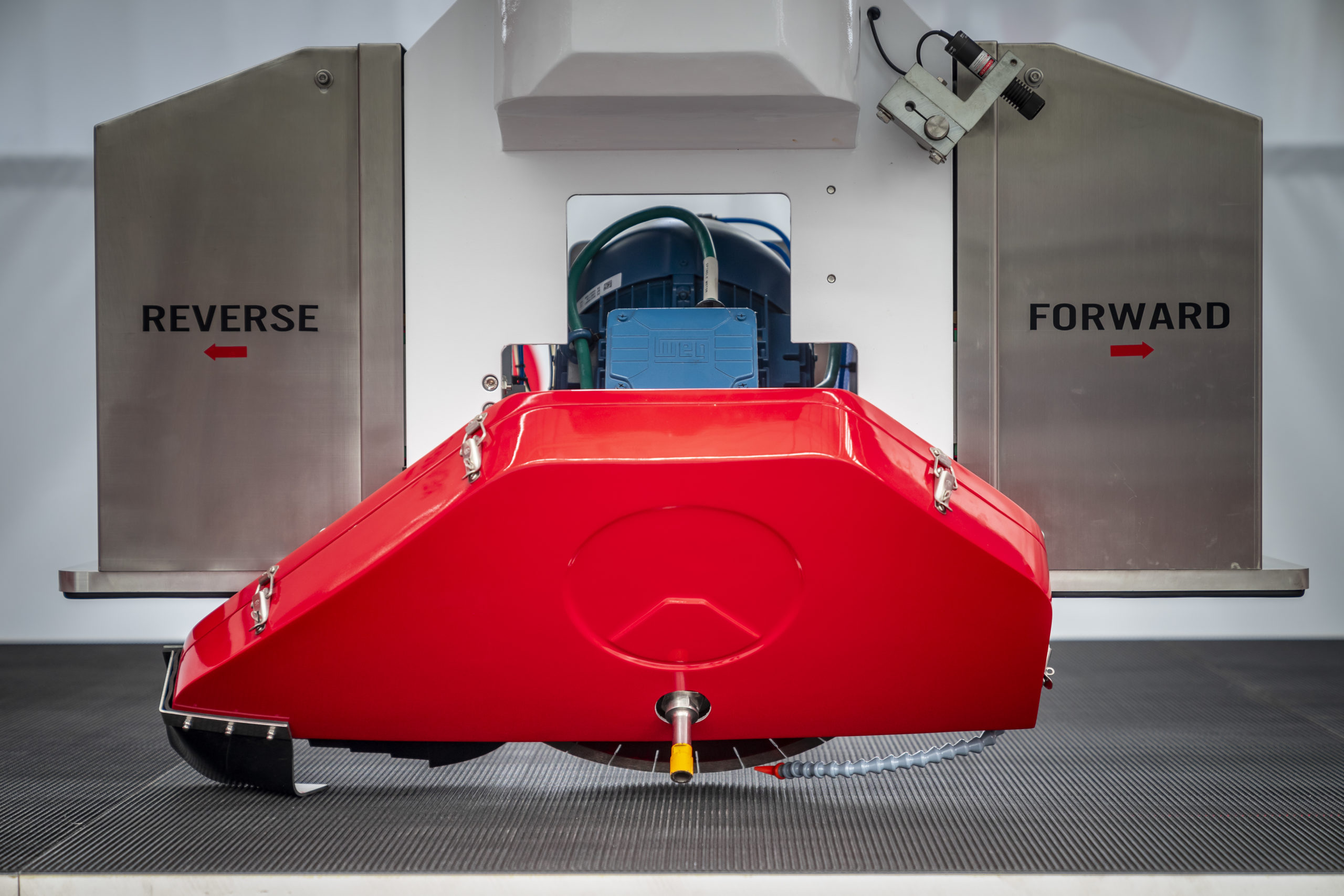

Fully automatic straight edge polishing

Production speeds of 80 to 150 l/f per hour

No height restrictions for material being processed

7 polishing heads enables processing in one pass

Requires small foot print for set up and operation (Dimensions are 14’x6’)

The LCH 711 requires no human intervention to over see the operation and allows the operator to do other jobs

Cost of lineal feet of finished edge amortized over 5 years is under .30 per foot

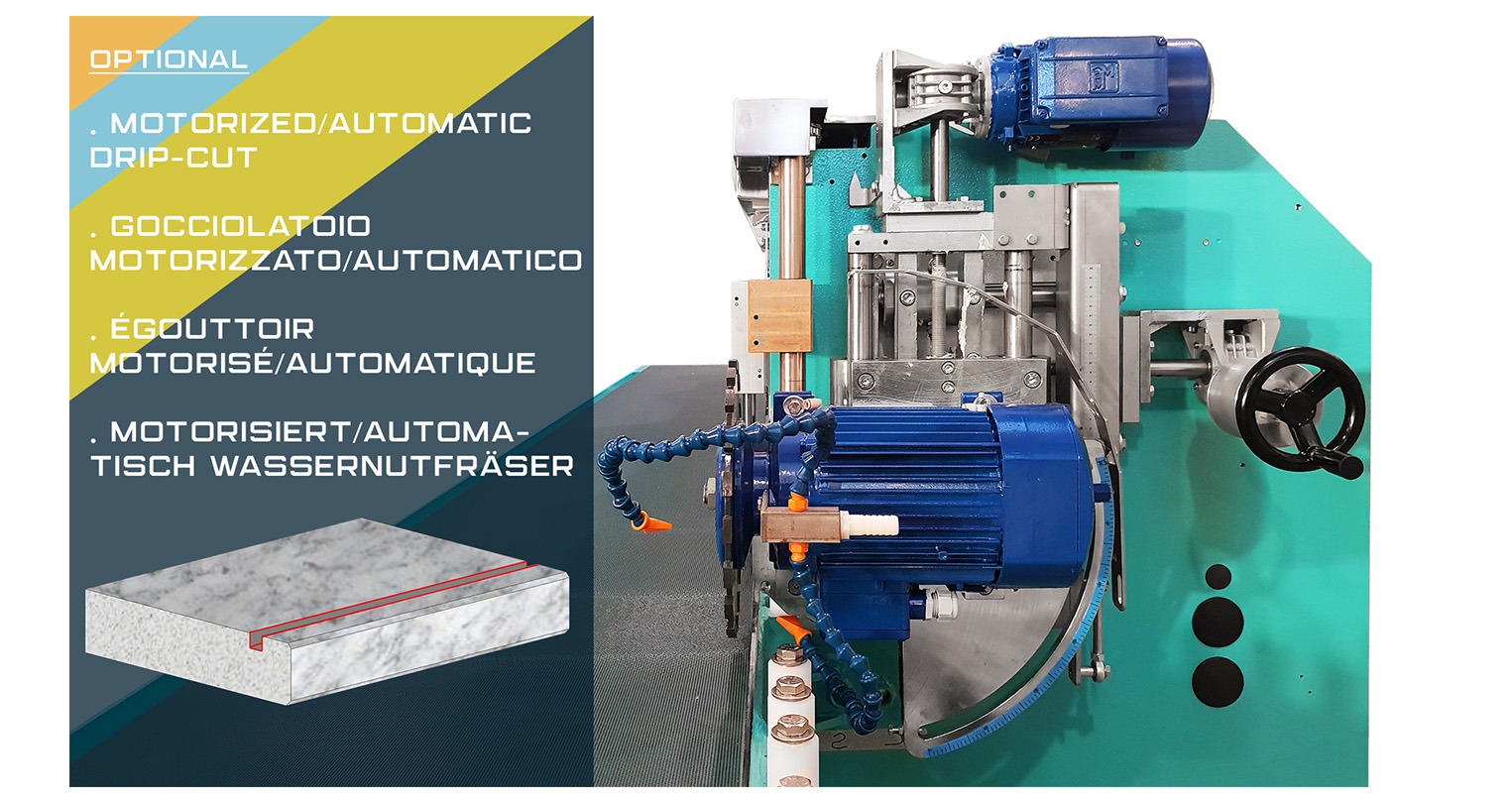

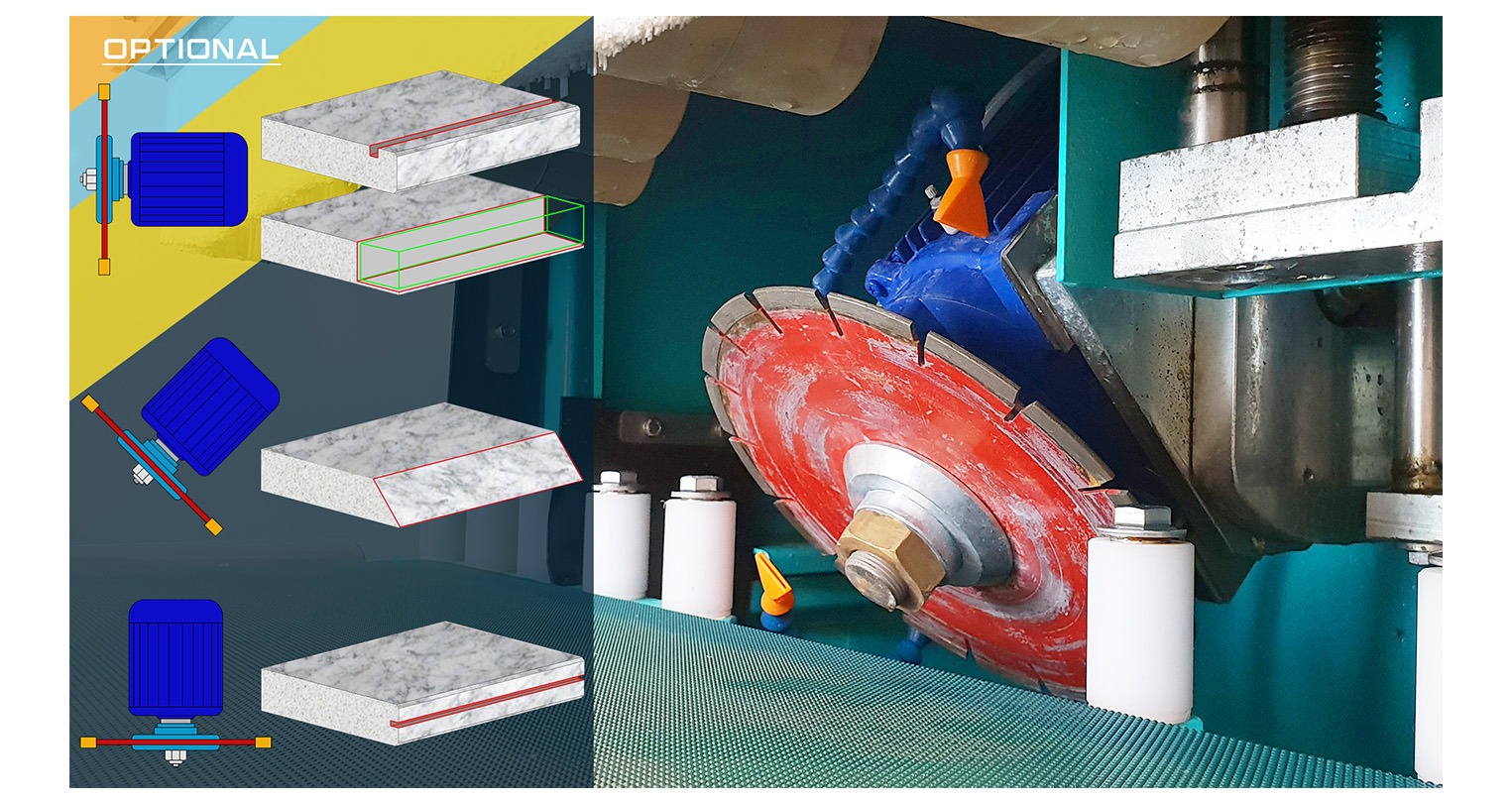

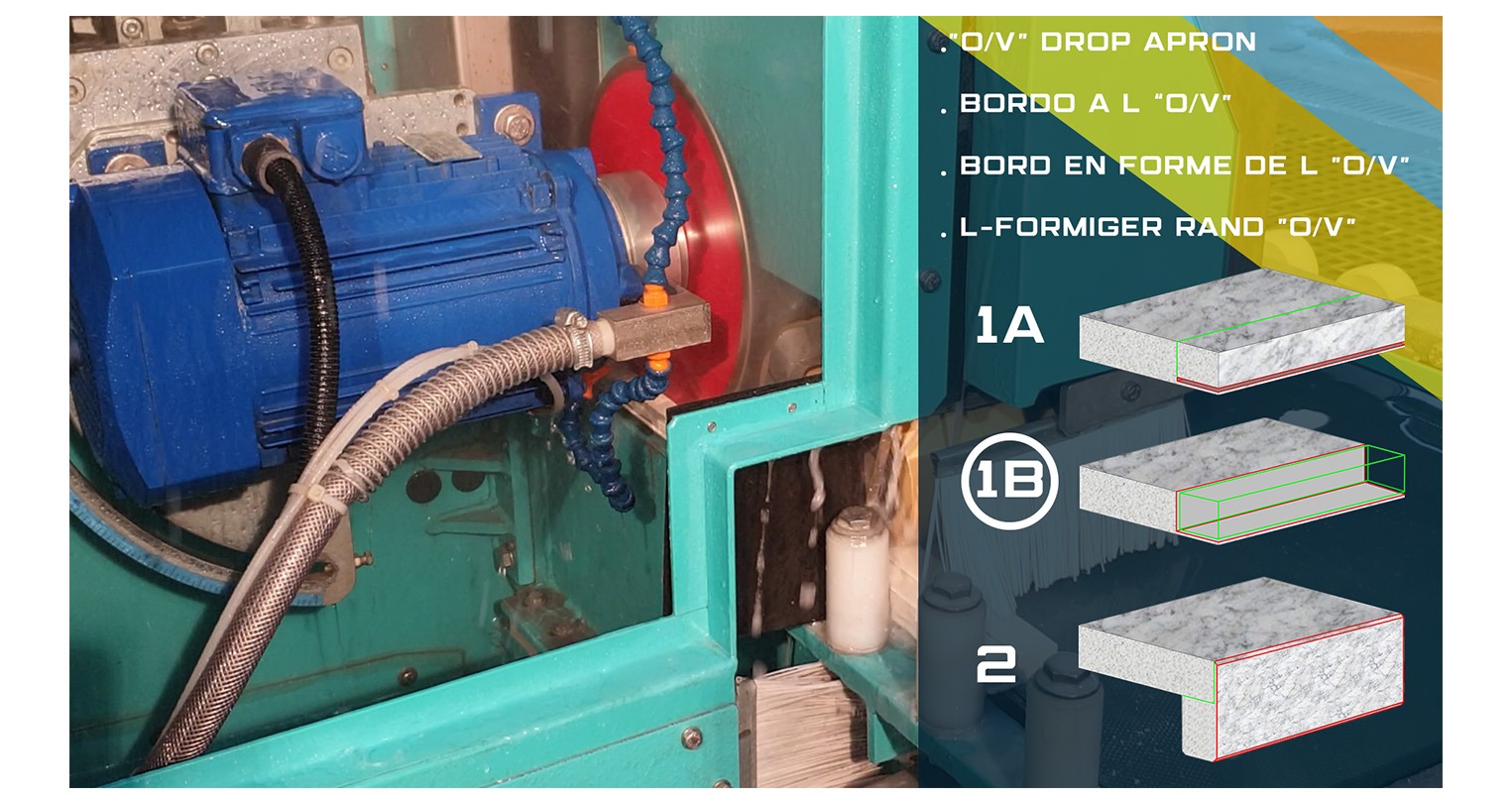

2 motors allow for V-grooving material for mitered edge