Description

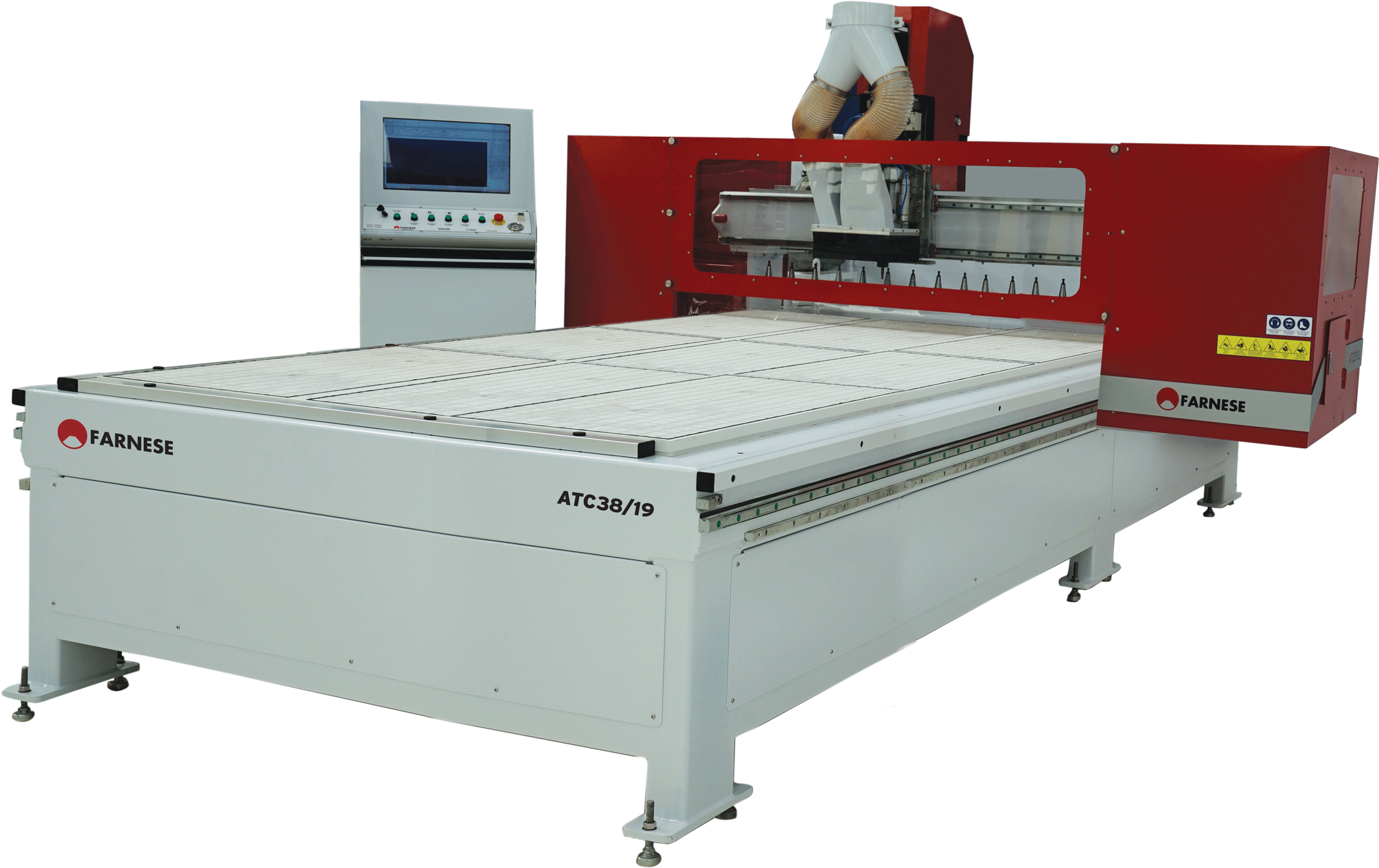

TABLE SIZE

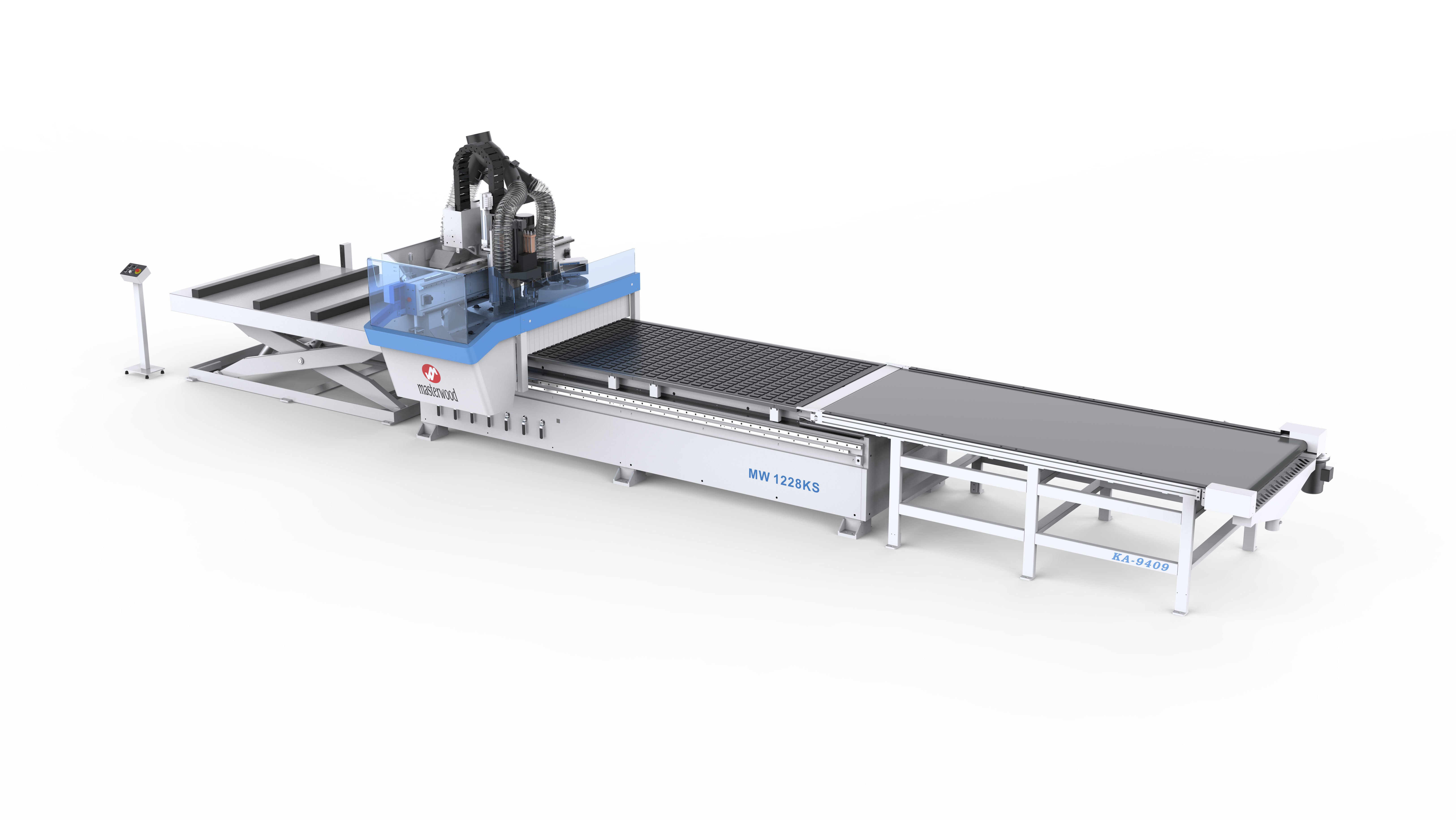

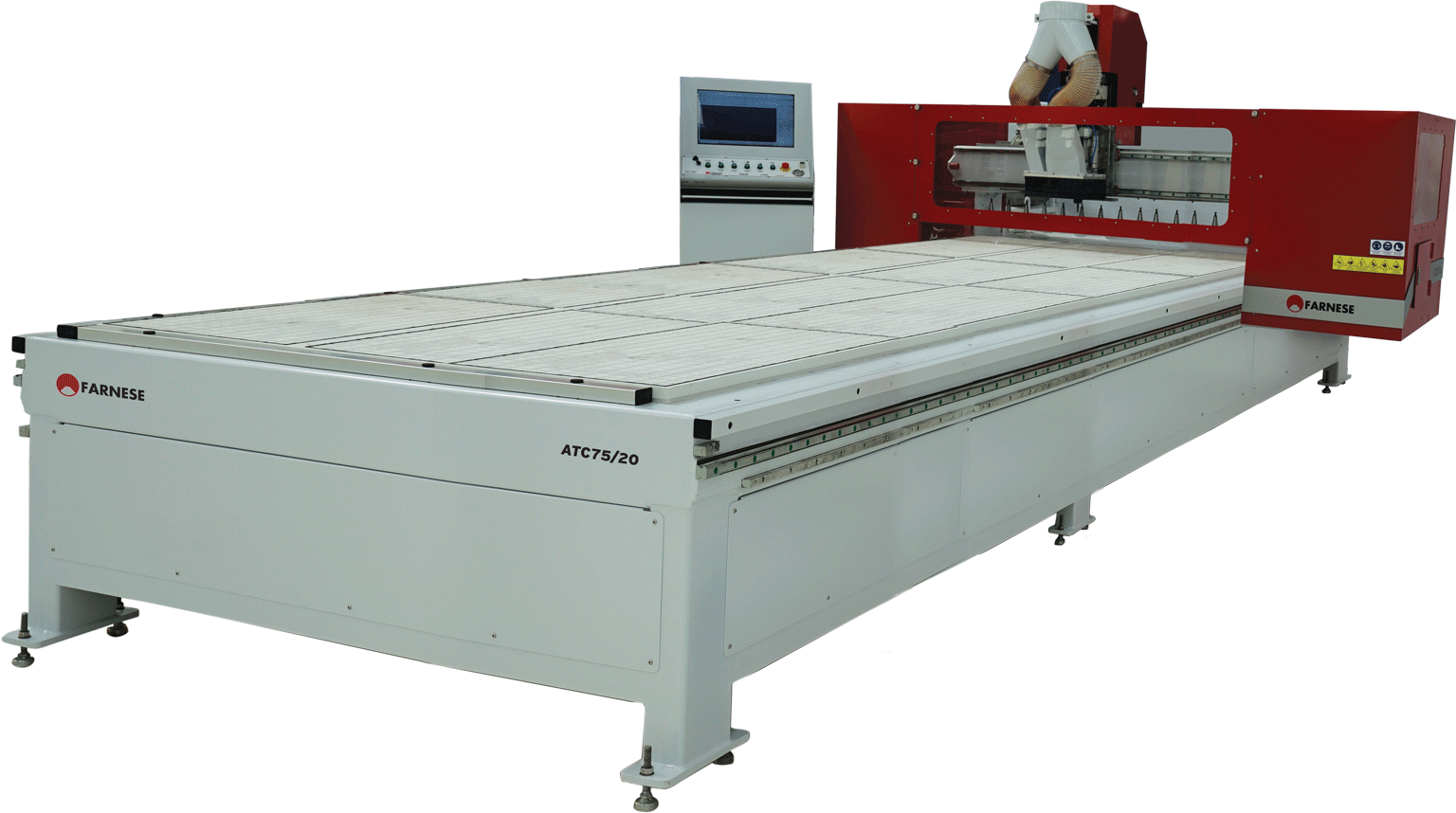

Table size: 2000mm x 7500mm

Larger models up to 2100mm x 11000mm available

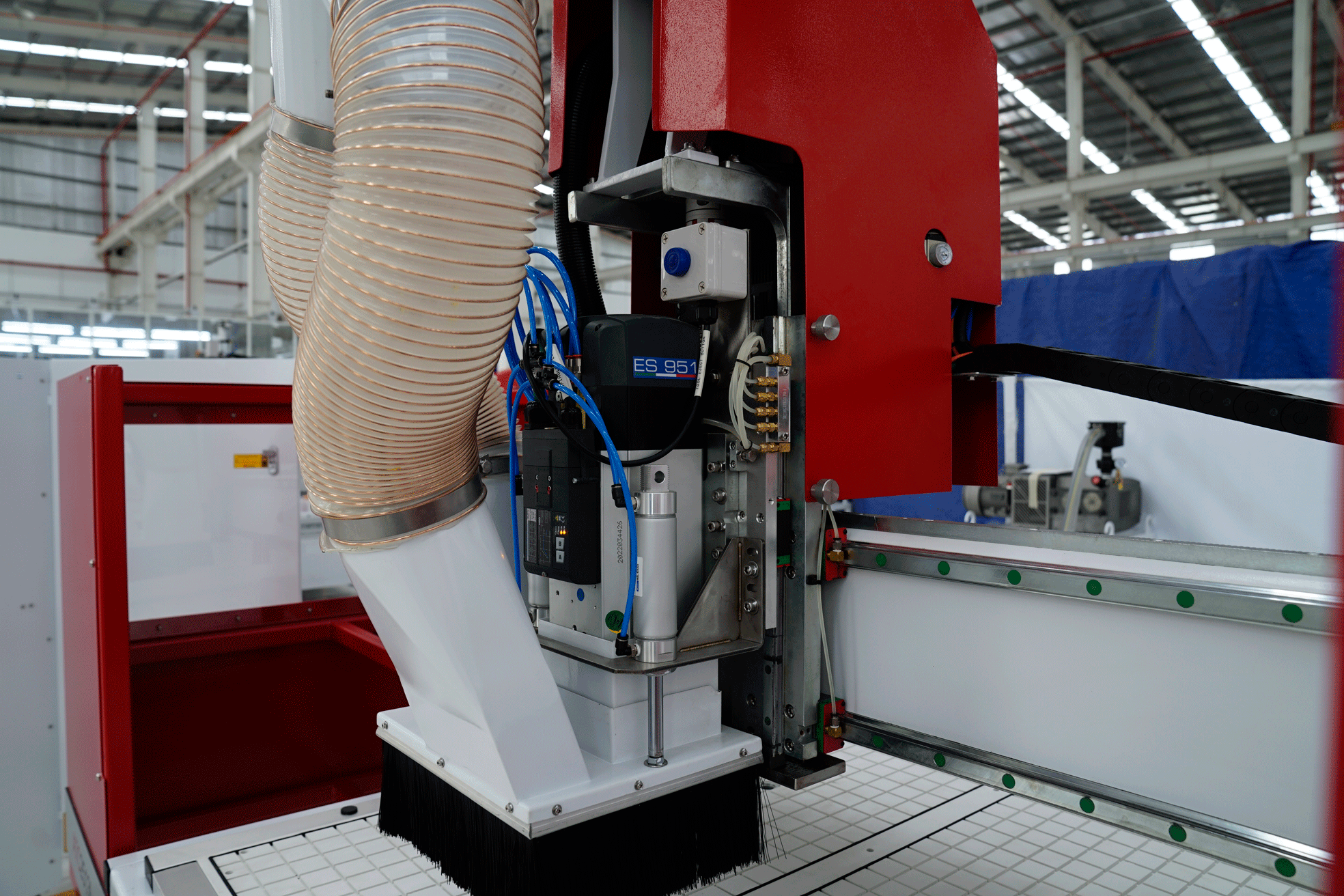

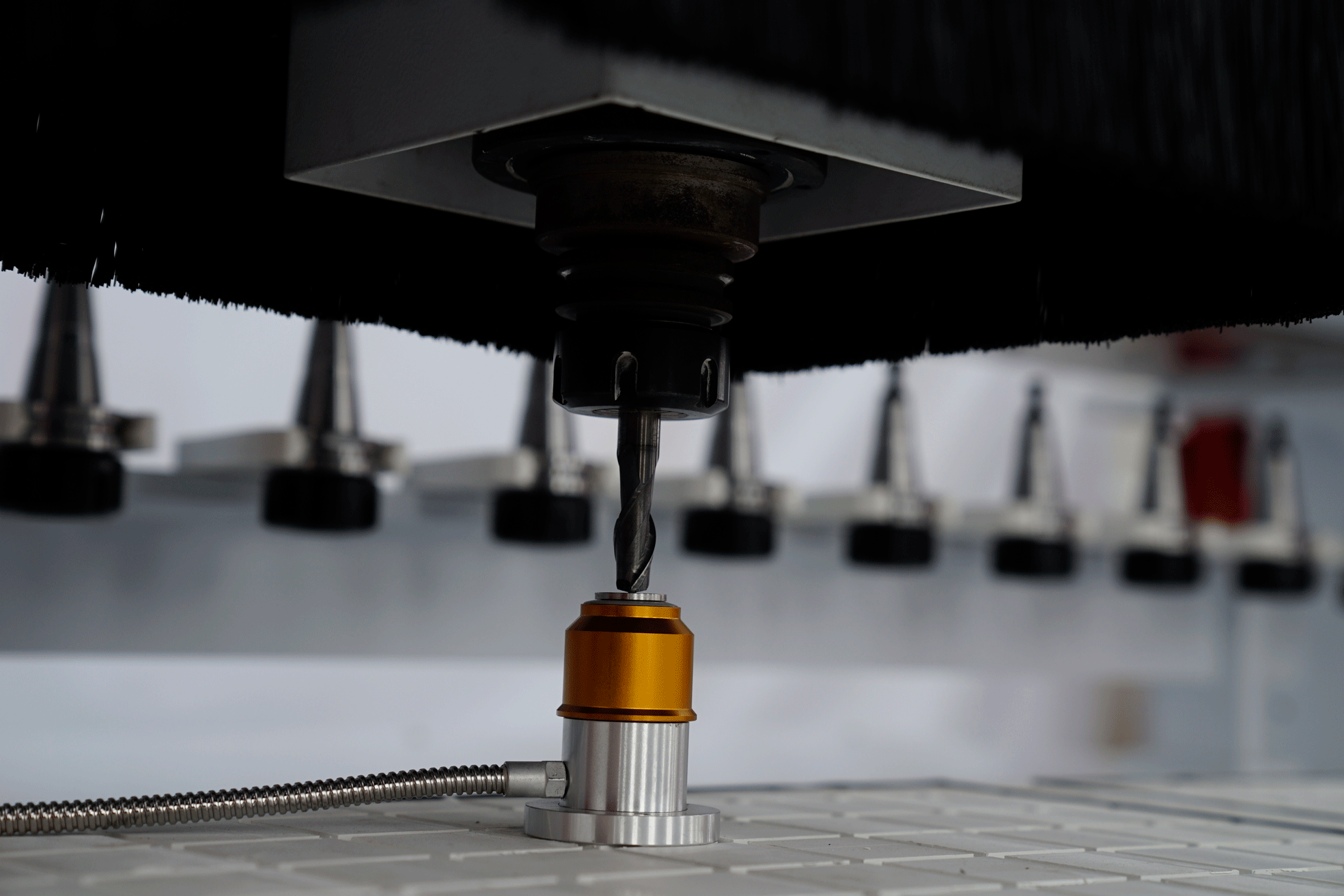

SPINDLE

High precision heavy-duty 9kW (12.0Hp) HSD router with internal cooling fan and ISO30 collet. Manufactured in Italy, HSD routers are renowned worldwide for their superior quality and durability. The Automatic tool change feature combined with left or right spindle rotation make this a very versatile machine that is also suitable for counter tops.

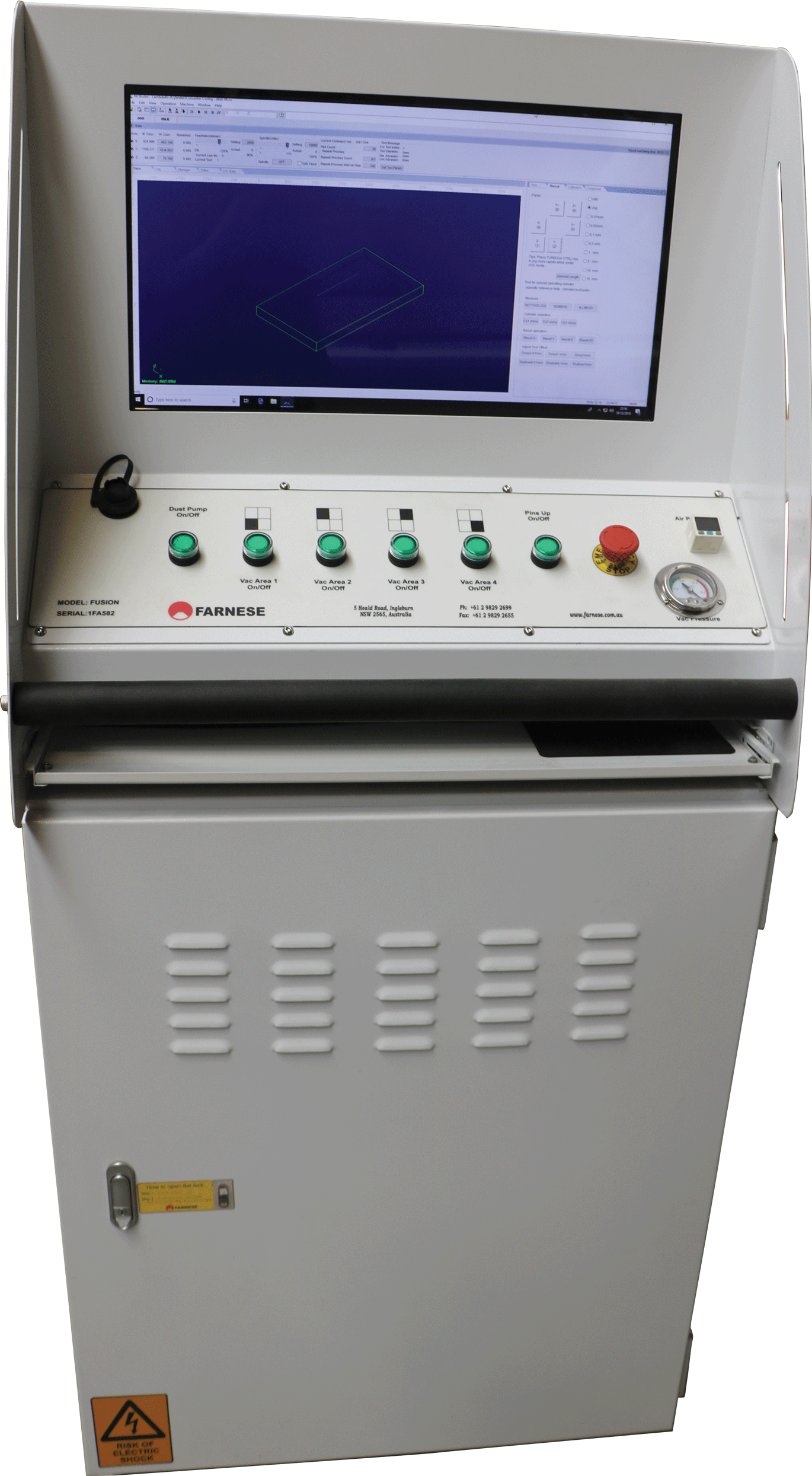

PC CONTROL

On-board PC with user friendly Windows 7 operating system. Network interface facility for file sharing. File format for the controller software configured in

- .NC.

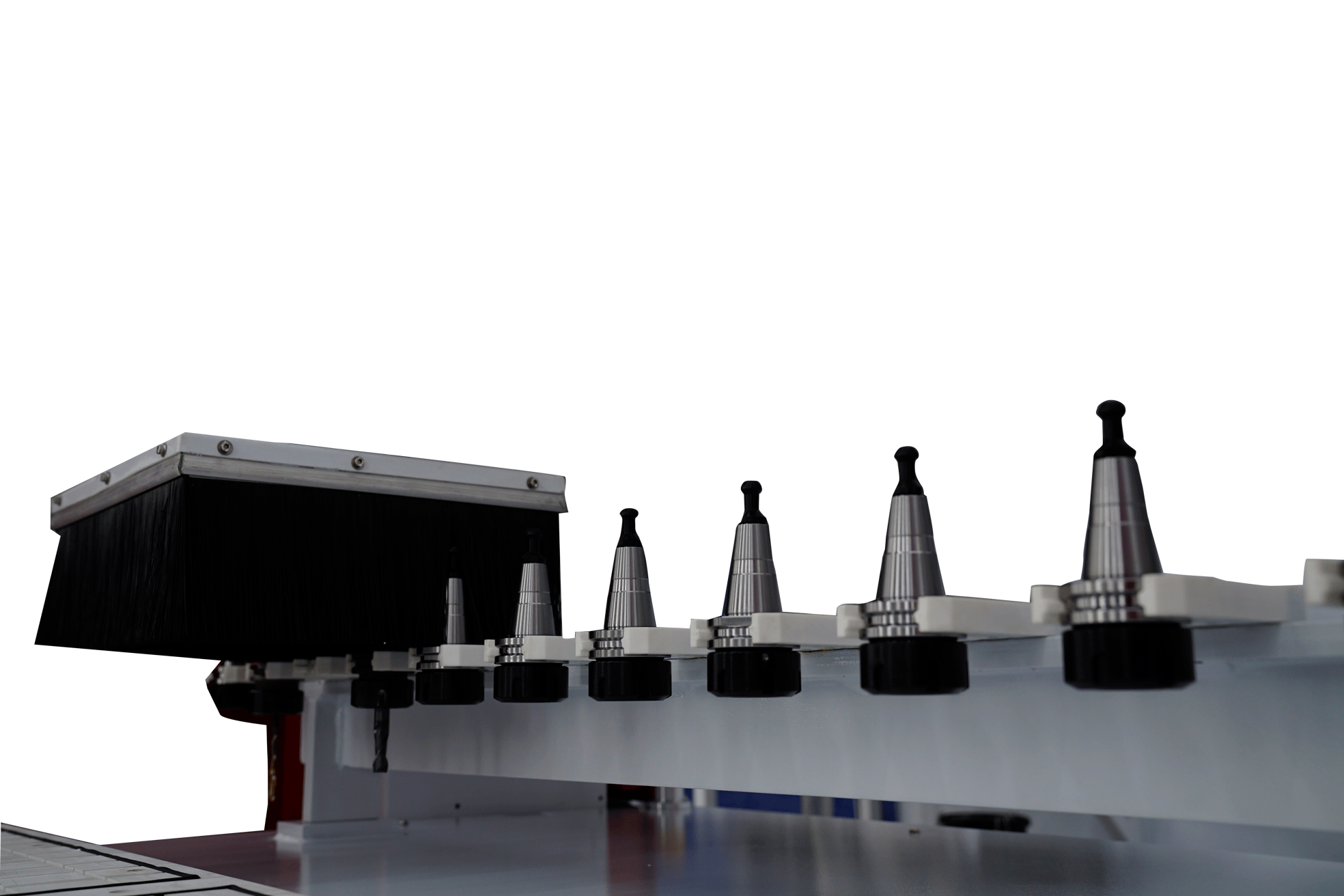

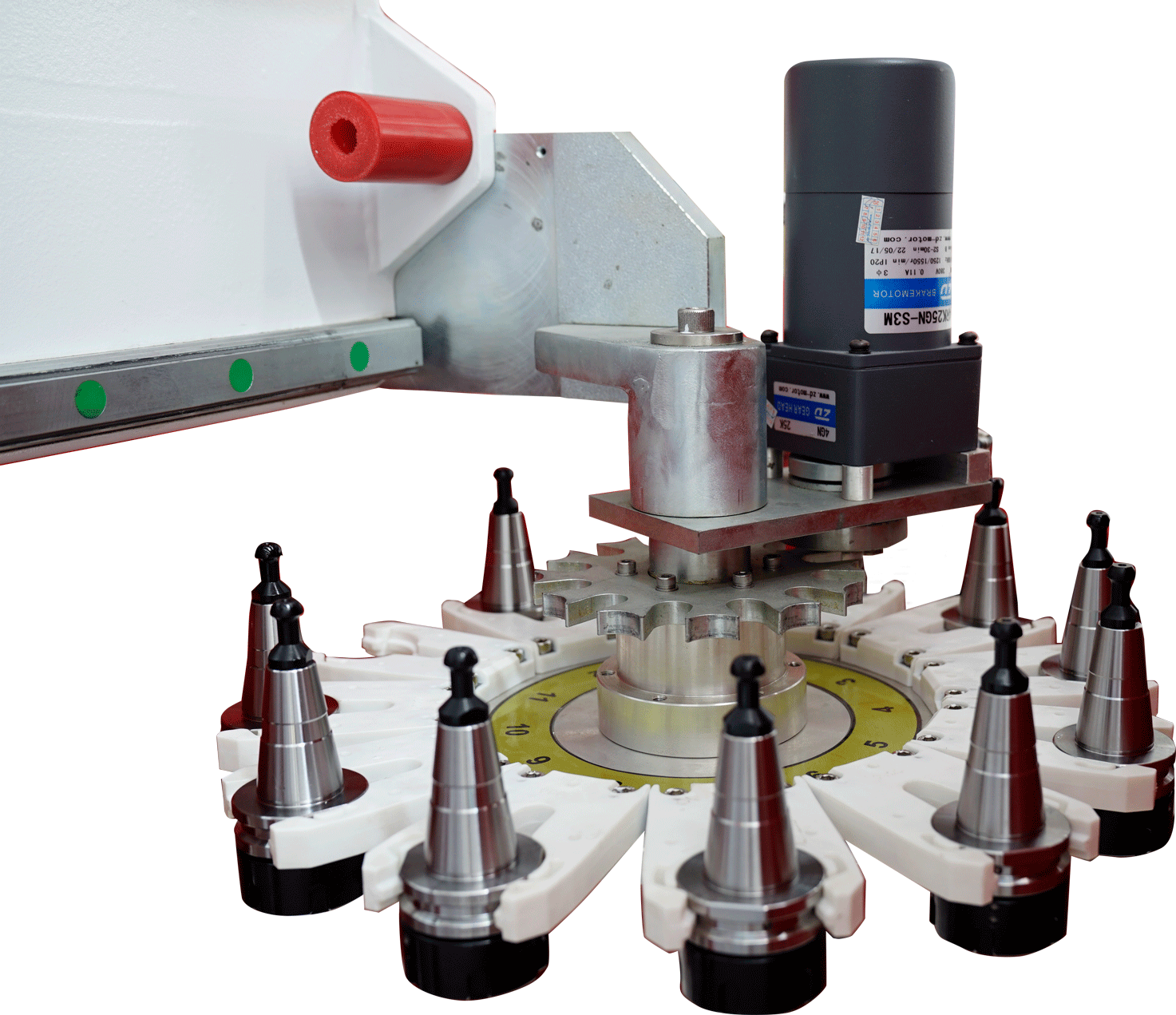

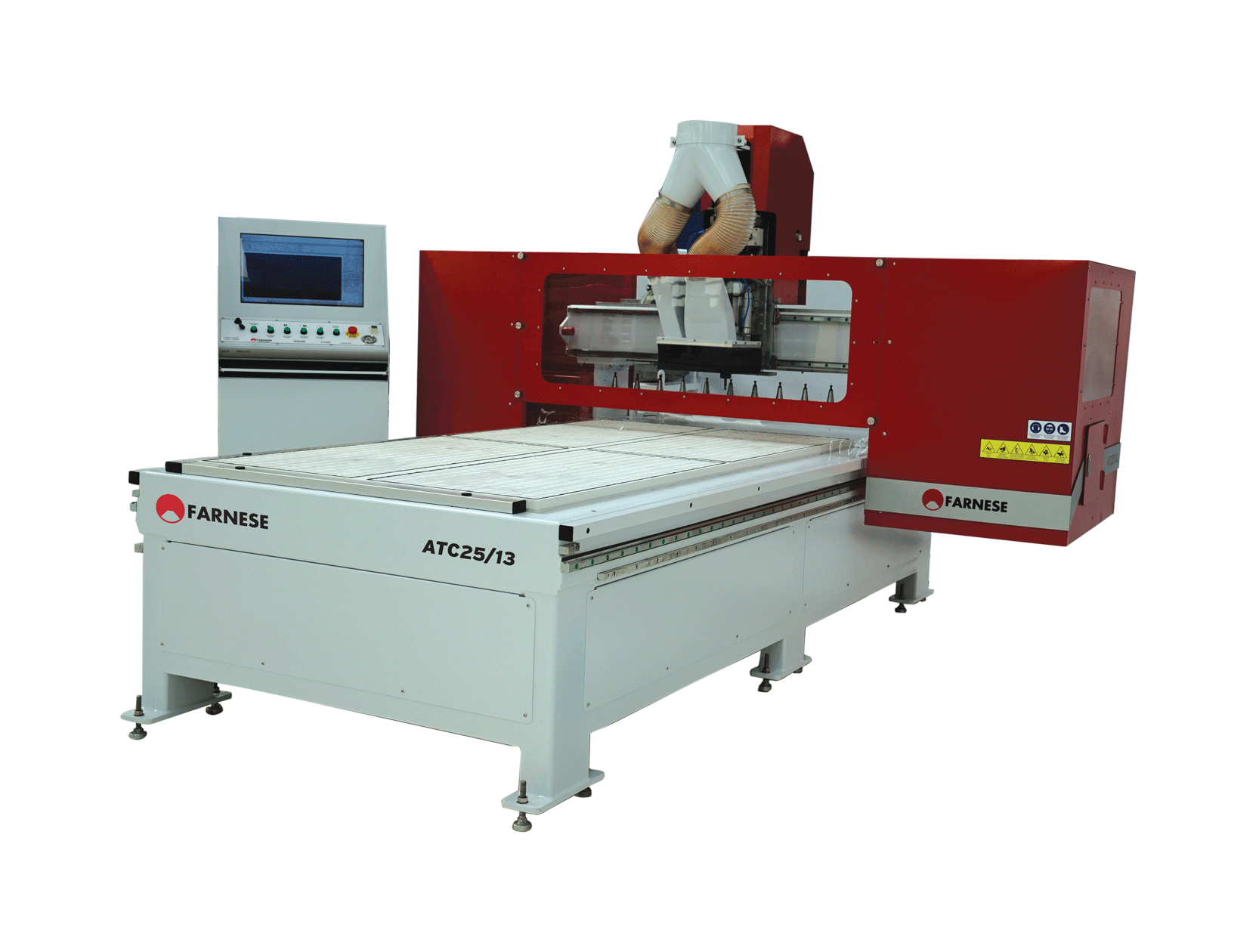

TOOL RACK

Rear mounted linear magazine with 16 tool capacity. Auto tool change via NC.

Optional 12 position Rotary Tool Changer

TOOL CALIBRATION PAD

The integrated sensor pad allows the operator to quickly and accurately calibrate each tool. The tool length is then automatically stored in the tool offset file.

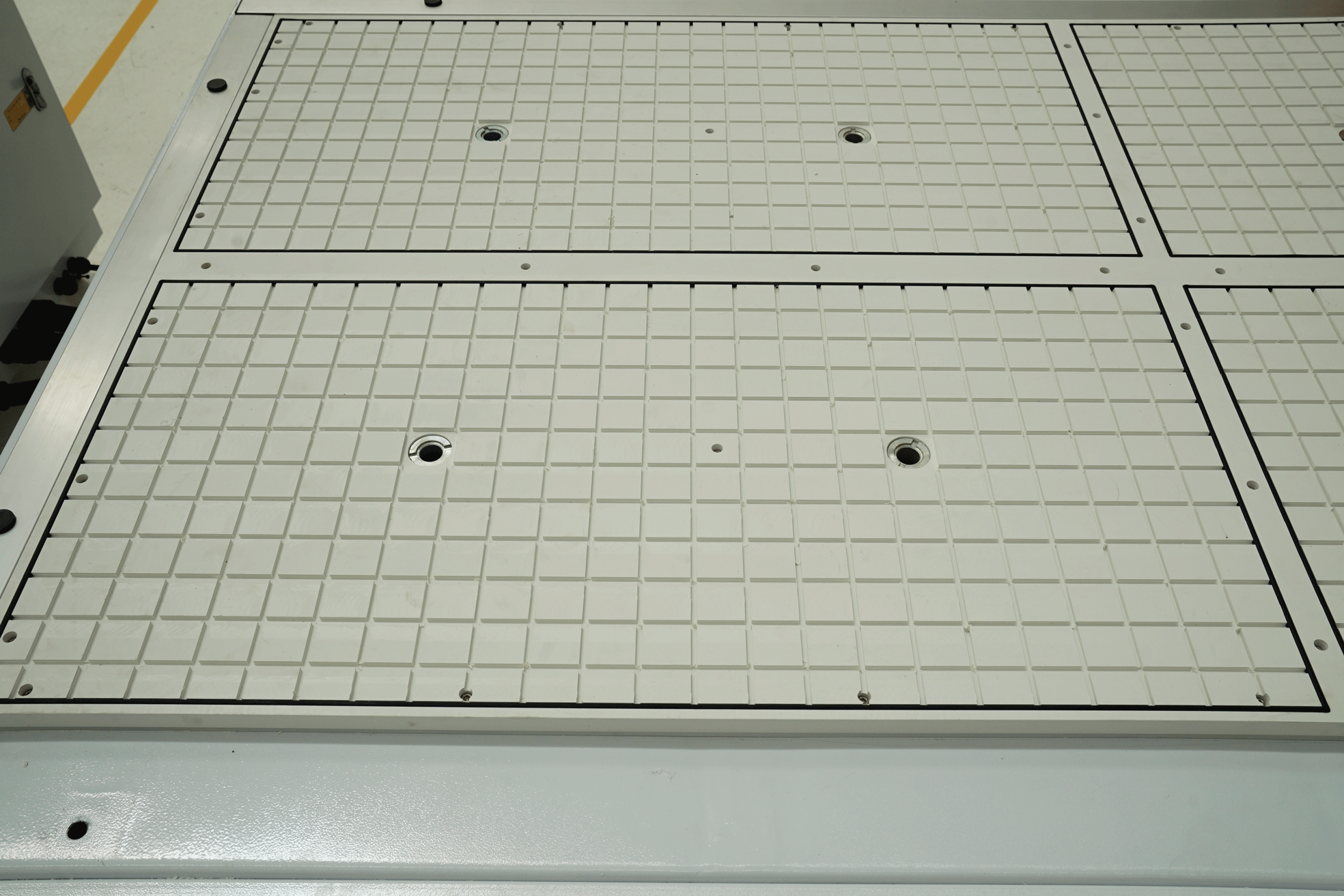

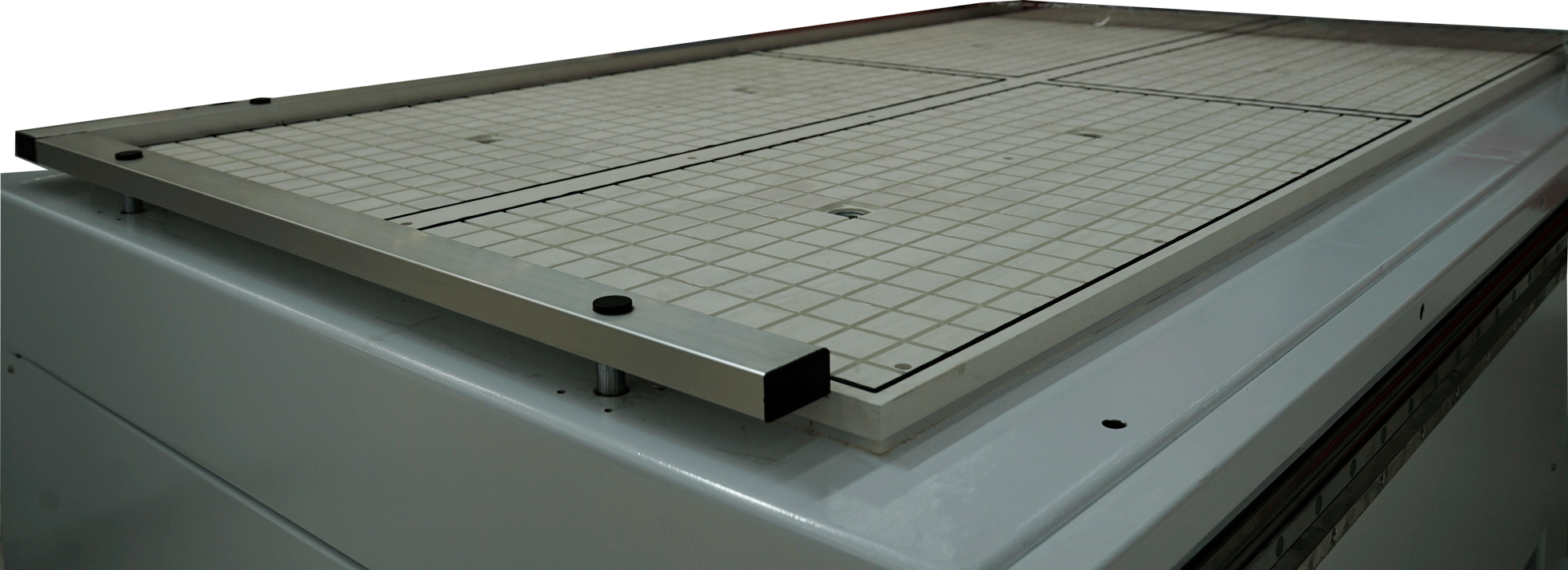

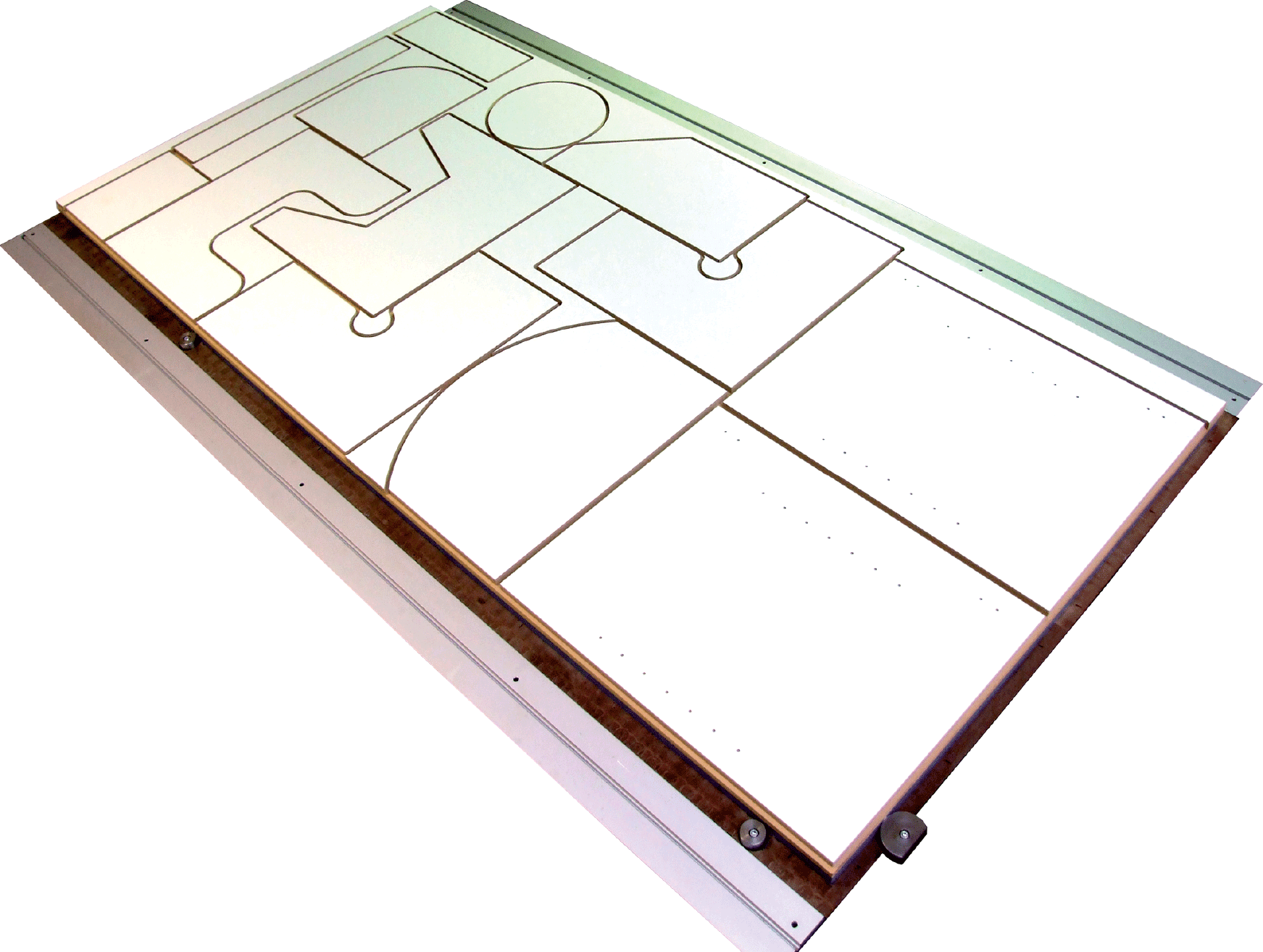

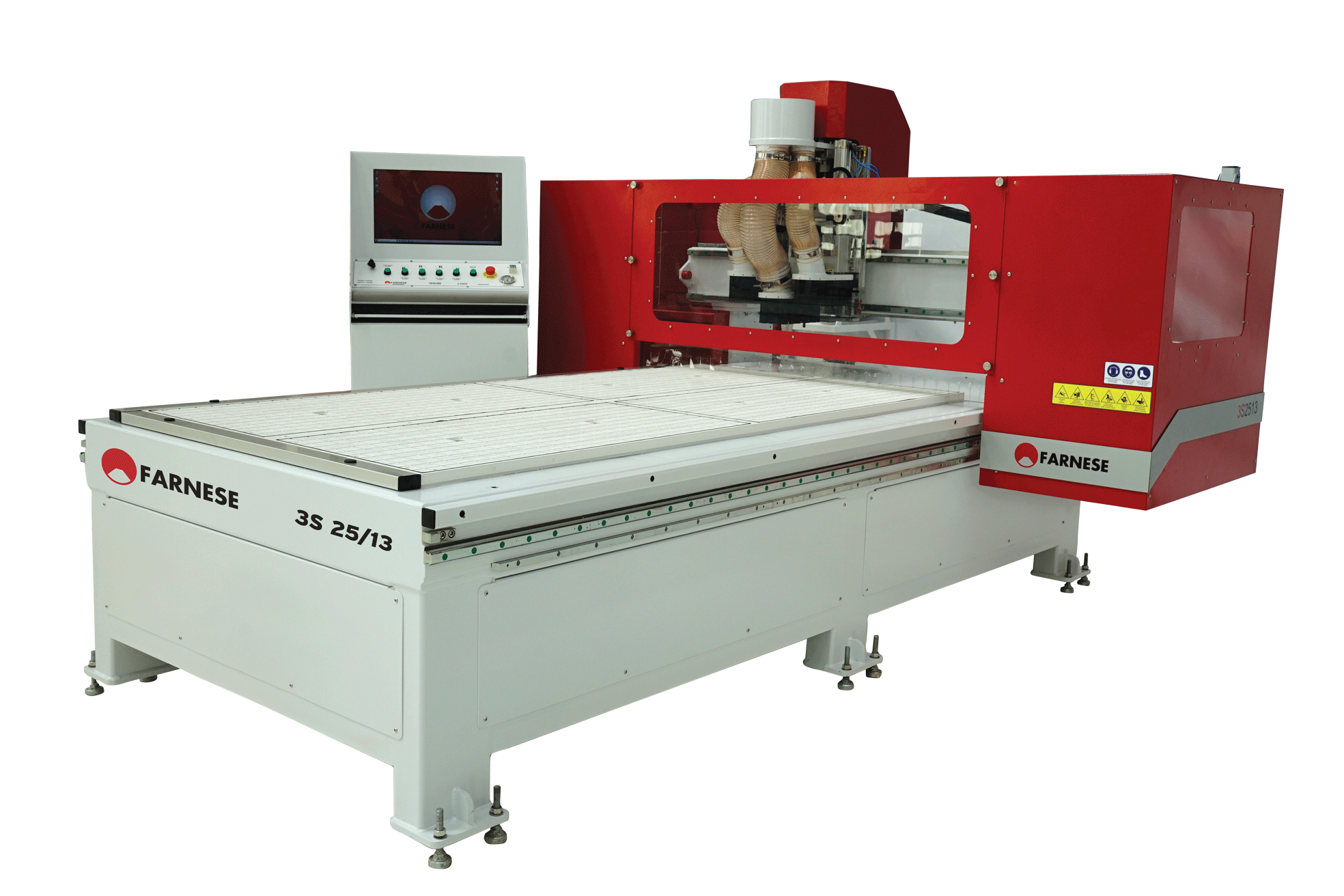

PHENOLIC TABLE TOP

There are 9 individually controlled vacuum zones. The table surface has a gasket matrix configuration with T-Slots along the Y axis, allowing various vacuum options e.g. spoilboards and jigs.

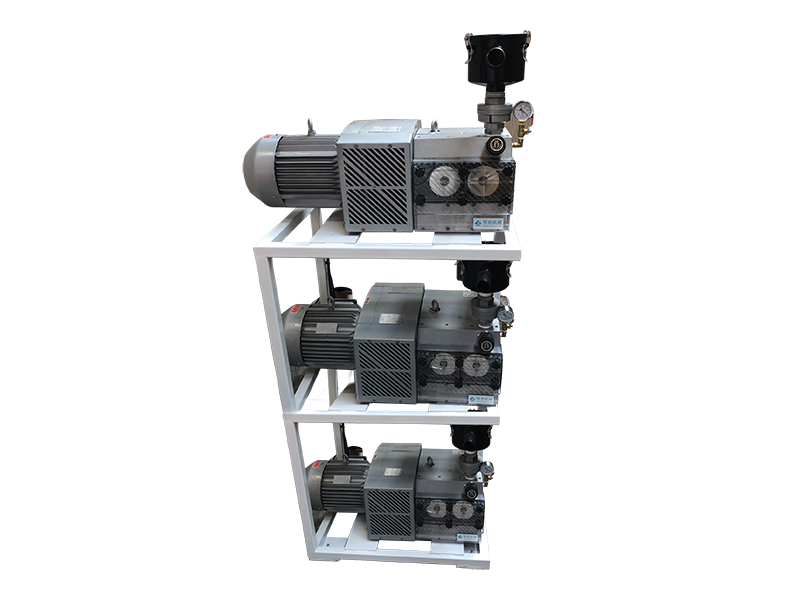

VACUUM PUMP

Vacuum for the table top is provided by Four quality 5.5kW (7.5Hp) rotary vane vacuum pumps. These Four pumps displaces 560 cubic metres per hour. Oil-free discharge gas is guaranteed, even in adverse operating conditions.

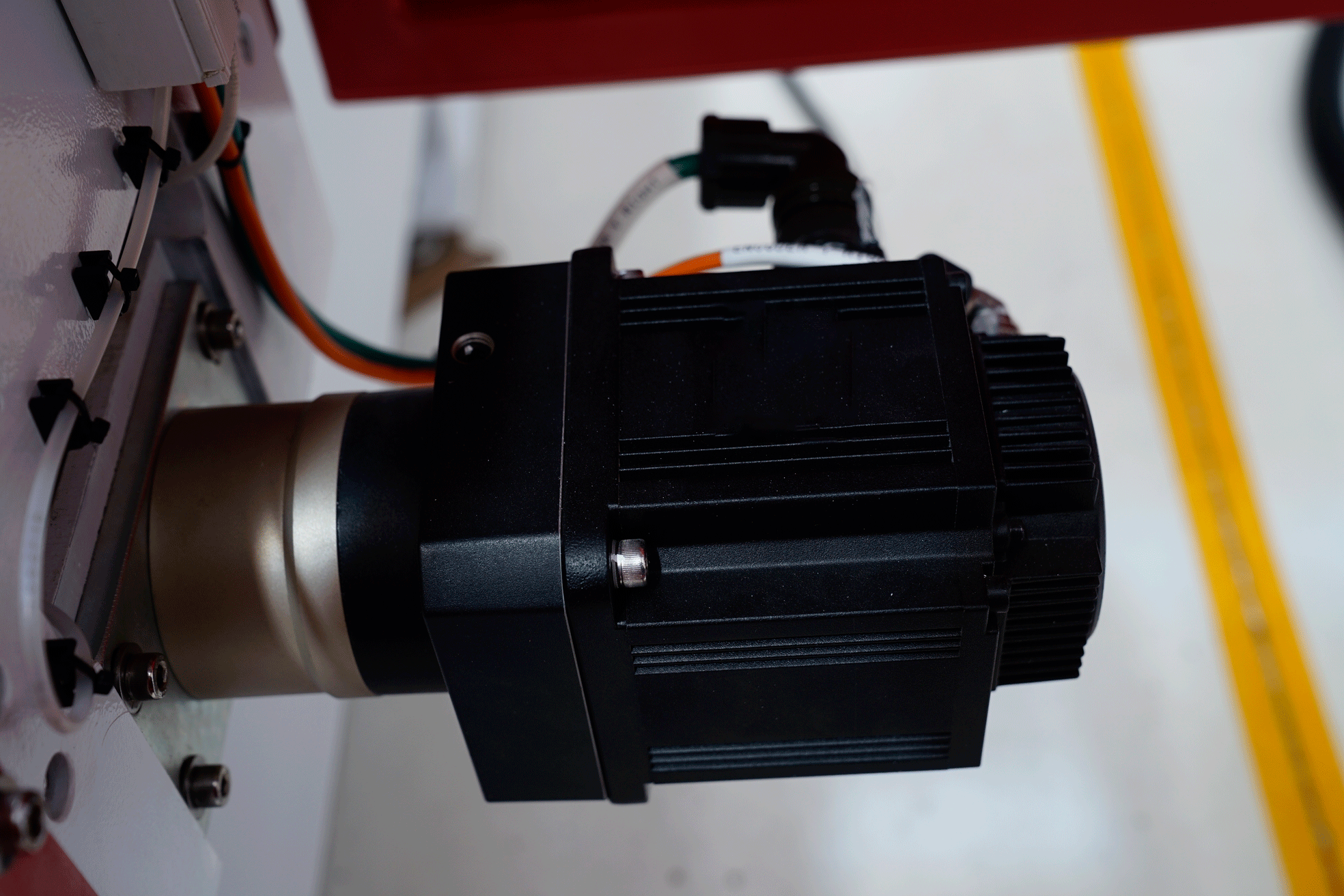

DRIVE GUIDE SYSTEM

Yaskawa Servo Motors

Superior quality linear guides and bearings units are used on all three of the machine’s axis. Precise movement along the X and Y axis is achieved via induction hardened rack and pinion drive systems. Z axis (vertical) movement accuracy is assured via a precision ground re-circulating ball screw.